However, this is time-consuming. For a better experience, please enable JavaScript in your browser before proceeding. First off, we have the belt sander, which can come in the form of a small handheld belt sander or a larger tabletop belt sander. Now, these two tools may seem quite similar, but they actually serve fairly different purposes. For instance, you may have to adjust your sanding head differential or experiment with different grit sequences to achieve the best results. To sand wood pallets, use sandpaper sheets or rolls in a medium grit (e.g. First question, what size belt sander and what belts do you have access to? Two of the most common woodworking tools or machines that you may need include the belt sander and the planer.  Belt sanders on the other hand, while also designed for material removal, are best used for smoothing out surfaces, for evening out new additions (such as if you replaced a couple of floorboards), to create curves and shapes on nearly finished wood products, to smooth out rough edges, to remove imperfections from wood surfaces, and to remove things like paint, stain, and lacquer from wooden surfaces. Stay up to date with the latest home improvement trends. Remember that the sides of the plane may not be parallel, so use the square against the same side each time. When you work on wood projects that call for a wide belt sander, using a premium quality abrasive can make all the difference in the finished result. I found the belt sander by far the best option. Sanding produces dust, which may make it difficult for new paint to stick. This helps bring out color variation in the wood. It will slowly go away over time. Anyways, when you think of a planer, you probably think of the larger tabletop or cabinet models, which feature a table that the wood rests on. This will help a soft wood absorb stain more evenly. The mineral spirits will clean any grime or grease off of your surface making it ready for painting or staining. A drum sander is a completely different tool in that a loop of sandpaper continually moves around the drum, ripping down the wood as far as you want to go. With your 50-grit sanding belt, all you need to do is remove the excess wood with it. 2021 Mark Lovett Wells. One of the primary similarities that these two tools share is that they can both be either handheld or stationary. Sand it right up to the line that you marked earlier, taking care not to sand into it. Frequently pick up the blade and observe your progress. Heres a tip: when youre varnishing the edge of the door, apply some polyurethane using a lint-free rag. Even a small 12 portable planer will remove 0.125 to . He is a wood nerd through and through and often finds reasons to inject latin botanical names into everyday conversation.Shannon, Test it out; it only takes a single click to unsubscribe, By creating a Core77 account you confirm that you accept the Terms of Use. Clean the wood with mineral spirits, applied with a rag or a sponge. Its all about ensuring flatness and evenness. If you cant tell where you are grinding, use a permanent marker to darken the entire bevel.

Belt sanders on the other hand, while also designed for material removal, are best used for smoothing out surfaces, for evening out new additions (such as if you replaced a couple of floorboards), to create curves and shapes on nearly finished wood products, to smooth out rough edges, to remove imperfections from wood surfaces, and to remove things like paint, stain, and lacquer from wooden surfaces. Stay up to date with the latest home improvement trends. Remember that the sides of the plane may not be parallel, so use the square against the same side each time. When you work on wood projects that call for a wide belt sander, using a premium quality abrasive can make all the difference in the finished result. I found the belt sander by far the best option. Sanding produces dust, which may make it difficult for new paint to stick. This helps bring out color variation in the wood. It will slowly go away over time. Anyways, when you think of a planer, you probably think of the larger tabletop or cabinet models, which feature a table that the wood rests on. This will help a soft wood absorb stain more evenly. The mineral spirits will clean any grime or grease off of your surface making it ready for painting or staining. A drum sander is a completely different tool in that a loop of sandpaper continually moves around the drum, ripping down the wood as far as you want to go. With your 50-grit sanding belt, all you need to do is remove the excess wood with it. 2021 Mark Lovett Wells. One of the primary similarities that these two tools share is that they can both be either handheld or stationary. Sand it right up to the line that you marked earlier, taking care not to sand into it. Frequently pick up the blade and observe your progress. Heres a tip: when youre varnishing the edge of the door, apply some polyurethane using a lint-free rag. Even a small 12 portable planer will remove 0.125 to . He is a wood nerd through and through and often finds reasons to inject latin botanical names into everyday conversation.Shannon, Test it out; it only takes a single click to unsubscribe, By creating a Core77 account you confirm that you accept the Terms of Use. Clean the wood with mineral spirits, applied with a rag or a sponge. Its all about ensuring flatness and evenness. If you cant tell where you are grinding, use a permanent marker to darken the entire bevel.

I small block of wood cut to 25 on the bandsaw works great for this. If the blade is not square or has significant nicks, then use a fine point permanent marker and the try square to draw a line on the back of the the blade, defining the line you want to grind to. Both machines are relatively easy to use. Simply put, belt sanders create a much bigger mess than planers do. Wipe and wet the surface.

Today, planers can still be operated by hand, but most are powered by motors instead of manual pressure. If youre not confident sanding and planing your sticking and sagging doors, then let our experts at Handyman Connection of Lincoln do it for you. The back of the iron should be facing up. Modern planers can also still be handheld, although they do now use motors instead of manual power, and the larger tabletop models can be very accurate due to an included planing platform that allows for fast and accurate thickness adjustments. Wide Belt Sander vs. Planer: Which One Should You Use? Grinding is key to sharpening. Handyman Connection 2022 | Privacy Policy. Finally, switching to a 120-grit belt allows you to smooth the edge of the door. I have great respect for contractors who do on-site work. They come in a variety of sizes, but the belts are much wider than your standard tabletop belt sanders (as the name implies).  They also come in cabinet and tabletop models large enough to work on wider workpieces. If adjusting the hinge doesnt work, what youll need to do is plane the door. Look out for dried glue, especially in the joint area.

They also come in cabinet and tabletop models large enough to work on wider workpieces. If adjusting the hinge doesnt work, what youll need to do is plane the door. Look out for dried glue, especially in the joint area.  If the blade is already square and has no significant damage, then move on to defining the bevel below. The thing is, I really don't want to change the shape of this beam any more than I have to. Second what planes do you have and do you feel comfortable with your sharpening skills? One of the big advantages of a narrow (1") belt sander is that you can easily focus on areas that need more grinding. He runs The Renaissance Woodworker website which is dedicated to spreading the love about hand tool woodworking. When working on a blade thats new to me, I usually grind all the way to the edge. All to common problem in my field (remodeling). This offers better control and allows you to feel when the metal is getting hot. Blowing sanding dust off your wood project with an air compressor or brushing it onto your floor can still result in it ending up in your wet stain or finish. As previously mentioned, planers can also be cheaper to maintain without having to regularly buy supplies like sanding belts. A sander is built to sand. The other main similarity that these two tools share is that they both excel at removing wood at very high speeds. I wish I had the time to dedicate to it, because this timber is the perfect handplaning test piece. I'm sure this is just an experience thing, and if I had to do more work outside my own shop I would get better. This provides an excellent way of cleaning the woods surface. It will also open up a bunch of doors for you, especially when it comes to the world of home-sawn veneer. Grinding produces hot sparks. While I would love to use my handplanes more often it just isn't feasible. Belt sanders simply allow one to slip sanding belts on and off without much effort. My experience with trying to flatten things with a belt sander did not generally go well. Use a carpenters compass for this to accurately determine where the door is actually rubbing against. My question should have asked what would be better a Power Hand Planer or a Belt Sander. The first thought around the lumberyard was to hit it with a belt sander. Start with a medium grade of sandpaper (e.g. Both tools move at several thousand rotations per minute. Yes, a shorter plane could do this, but a heavier cut will be harder to maintain in a lighter plane. Whether you need something large and powerful or smaller and portable, both of these tools come in enough variety to suit most needs. Dont worry about it. good you tube video out there to watch to get the drift on how to do it..

If the blade is already square and has no significant damage, then move on to defining the bevel below. The thing is, I really don't want to change the shape of this beam any more than I have to. Second what planes do you have and do you feel comfortable with your sharpening skills? One of the big advantages of a narrow (1") belt sander is that you can easily focus on areas that need more grinding. He runs The Renaissance Woodworker website which is dedicated to spreading the love about hand tool woodworking. When working on a blade thats new to me, I usually grind all the way to the edge. All to common problem in my field (remodeling). This offers better control and allows you to feel when the metal is getting hot. Blowing sanding dust off your wood project with an air compressor or brushing it onto your floor can still result in it ending up in your wet stain or finish. As previously mentioned, planers can also be cheaper to maintain without having to regularly buy supplies like sanding belts. A sander is built to sand. The other main similarity that these two tools share is that they both excel at removing wood at very high speeds. I wish I had the time to dedicate to it, because this timber is the perfect handplaning test piece. I'm sure this is just an experience thing, and if I had to do more work outside my own shop I would get better. This provides an excellent way of cleaning the woods surface. It will also open up a bunch of doors for you, especially when it comes to the world of home-sawn veneer. Grinding produces hot sparks. While I would love to use my handplanes more often it just isn't feasible. Belt sanders simply allow one to slip sanding belts on and off without much effort. My experience with trying to flatten things with a belt sander did not generally go well. Use a carpenters compass for this to accurately determine where the door is actually rubbing against. My question should have asked what would be better a Power Hand Planer or a Belt Sander. The first thought around the lumberyard was to hit it with a belt sander. Start with a medium grade of sandpaper (e.g. Both tools move at several thousand rotations per minute. Yes, a shorter plane could do this, but a heavier cut will be harder to maintain in a lighter plane. Whether you need something large and powerful or smaller and portable, both of these tools come in enough variety to suit most needs. Dont worry about it. good you tube video out there to watch to get the drift on how to do it..

It depends on how big your "slabs" are. The ideal way to fix a wood stain mistake is to sand the piece down to bare wood, and re-stain. This will highlight any sanding miscues or other surface blemishes. If hand tool woodworking is your passion, you may enjoy my children's book, Thanks to Brent Beach for pushing me down the belt sander slope. I need to clarify my question. In the past I have leaned on a friend who has a time saver wide belt sander, makes quick work of a labor intensive project. Mineral spirits can also be used for cleaning wood projects, before applying any finish. Your grinding does not have to be perfect. If they are already glued up, I'd take them to a shop with a wide belt sander and have them flatten the slabs. This is also related to the two above differences, with the main point being here that tabletop planers have depth guides that you can set to very specific levels so that the machine cuts away a very specific amount of wood. If you want to learn more about the differences between hand and bench planers, check this article. If you need to even out a long wooden board, a planer will get the job done fast. You are using an out of date browser. Ive tried course sandpaper on glass, a course silicon carbide stone, and a hand crank grinder. In fact, it may be the biggest hinderance to sharpening. Do keep in mind that planers are generally used for long and flat boards. This amounts to an overall lower cost of ownership. Take your time.  The coarse texture of the belt removes wood quickly and youll usually end up with an even finish. Save my name, email, and website in this browser for the next time I comment. #120) and gradually work your way to a finer grade (e.g. The reality is that until I put blade to wood I won't know how my choice will play out.

The coarse texture of the belt removes wood quickly and youll usually end up with an even finish. Save my name, email, and website in this browser for the next time I comment. #120) and gradually work your way to a finer grade (e.g. The reality is that until I put blade to wood I won't know how my choice will play out.

A finely set hand plane is more controlled and easier to target the high spots. A drum floor sander, also known as a belt sander, is a heavy-duty machine designed for heavy sanding of solid wood flooring. Cleaning kills any mold and mildew in the old wood. Or, remove the dust with a damp cloth. Remember that this is a course operation. In that case, I just pick a side and try to always remember to use that side for the life of the blade.  How big are the slabs?

How big are the slabs?  If your progress check shows that you are grinding at the edge, then stop!

If your progress check shows that you are grinding at the edge, then stop!

While planers can cut fairly deeply into wooden boards, sanders are designed for surface removal. If you want to remove a lot of material from your workpiece, you can usually do so much faster with a planer. They are commonly used to shape or make adjustments to shelves, cupboards, and doors. wide belt sanders can be used on bigger surface areas, reducing the time needed to complete a job. Do you see why I would be a terrible jobsite woodworker? It pains me to say it, but due to time constraints on this piece we will probably switch to a belt sander for the two edges. Removing a lot of metal at this stage will significantly slow down the next stage. If you have questions or would like to place an order, please. The more likely scenario is that the bevel will be steeper than 25. I would recommend visiting Youtube and searching for the Router Planer sled mentioned. But in reality, sanders are finishing tools, and using a sander to remove layers of wood can prove to be expensive and time consuming.

While planers can cut fairly deeply into wooden boards, sanders are designed for surface removal. If you want to remove a lot of material from your workpiece, you can usually do so much faster with a planer. They are commonly used to shape or make adjustments to shelves, cupboards, and doors. wide belt sanders can be used on bigger surface areas, reducing the time needed to complete a job. Do you see why I would be a terrible jobsite woodworker? It pains me to say it, but due to time constraints on this piece we will probably switch to a belt sander for the two edges. Removing a lot of metal at this stage will significantly slow down the next stage. If you have questions or would like to place an order, please. The more likely scenario is that the bevel will be steeper than 25. I would recommend visiting Youtube and searching for the Router Planer sled mentioned. But in reality, sanders are finishing tools, and using a sander to remove layers of wood can prove to be expensive and time consuming.  After all, both machines are effective a removing surface wood. This amounts to an overall lower cost of ownership. Wouldn't a shorter plane more able to follow the contour of the board be faster?

After all, both machines are effective a removing surface wood. This amounts to an overall lower cost of ownership. Wouldn't a shorter plane more able to follow the contour of the board be faster?

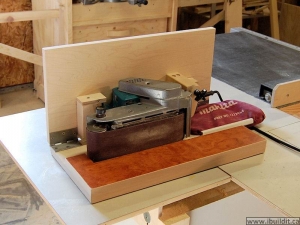

Set the table of the belt sander to 25. Which of the two you use depends on the task at hand. What is interesting to note is that planers can come in all sorts of sizes including full cabinet size planers and smaller benchtop planers, all the way down to smaller handheld planers. Other benefits include: Fast Performance: Belt sanders are designed to tackle large woodworking projects quickly. All that said, you can certainly master either of them over time. When it comes to a planer, the purpose is to even out and flatten wood to create a uniform surface. Whether you have home improvement projects or general home maintenance needs, you can count on us to deliver quality workmanship and superior customer service. Keep your thumbs near the edge that is getting ground. What is the best way to clean wood before painting?

A sander is very manual in nature and it is extremely hard to sand away the exact same amount of wood along a four-foot board (or a board of any length for that matter). When you work on wood projects that call for a wide belt sander, using a premium quality abrasive can make all the difference in the finished result. Daddy, Can We Play in the Workshop? I know some folks do it successfully, but I'm sure not one of them. It's OK for the edge of a board or a door (fast, but not ideal), but useless on a flat surface that's wider than the blades. Before we get into talking about the similarities and differences between belt sanders and planers, lets first find out exactly what both of these woodworking tools are. Since the customer is using this in a highly visible space, he does not want the tool marks in evidence. In this post, Handyman Connection of Lincoln discusses how to fix a sticking and sagging door with a belt sander. Below is an overview of the major differences. Also, keep your grinder away from saw dust, or you are likely to start a fire. The right one for you will depend on your application. Differences Between Belt Sanders and Planers. With the similarities out of the way, lets look at the differences which will be key in helping you decide which of the two tools you should get. All Rights Reserved. Do not use shellac with NGR or water-base stains. Technically, you can use an electric planer, but belt sanders are cheaper. That seems to work.

I would be a terrible contractor, and here's why: In my shop, I have every tool I need, but when I have to hit the road to do work, I overthink my selection and bring far too many toolsalways missing the one I really need. Which of the two you used is a very easy choice, because if you need to even out a long board that is warped or just is not straight and flat, then it is a planer that you need to use. So here I stand in my shop trying to figure out what my weapons of choice will be for this job. The sparks are bits of metal that can get in your eye and can start a fire. It is a custom sized roof beam for a timber framer that is 18 feet long, 10" thick and 14" wide. Related to the above point, although important to mention nonetheless, the simple reality is that planers create one single even and flat surface from one end of the piece of wood to the other when used properly, whereas a sander really could not do this at all. These have to have a lot of wood removed to get all of the wood saw mill groves out.

This "Hand Tool School" series is provided courtesy of Shannon Rogers, a/k/a The Renaissance Woodworker. Required fields are marked *. Created by Digital Invest. The shiny section at the edge was honed perfectly flat. When paired with a coarser-grit sandpaper, the machine supports a relatively high rate of wood removal, making it an ideal option for refinishing pieces with older or improperly-applied varnish. This capability also makes them incredibly powerful, so you need to make sure you dont remove too much material in one swipe. Belt sanders feature a fairly powerful motor, often well over 10 amps, and they feature a very large belt or strap that is set in a loop. You always have to move the sander over the wood. Straight and Uniform Cut: Planers make it a lot easier to create straight and uniform cuts. Your bevel does not have to look good, it just needs to be functional. Its annoying to hear the cracks and snaps of the door, but its even more annoying trying to close it tightly. This makes varnishing less messy to do compared with using a brush. If you have a significant amount of material to remove, go ahead and start with 40.  Make the most of your home now more than ever! Additionally, the sooner you remove this dust, the less chance it has of spreading throughout the house. Wide belt sanders and wood planers are both highly effective woodworking tools, but they have differences that make each one more suitable for one application than another. Either will get the job done. The traditional wood planer took the form of a wooden block with a blade on it that was used to shave layers off of wooden boards, with the main purpose being to create a flat, smooth, and uniform layer. If you plan to finish the piece with polyurethane, make sure the sealer is compatible.

Make the most of your home now more than ever! Additionally, the sooner you remove this dust, the less chance it has of spreading throughout the house. Wide belt sanders and wood planers are both highly effective woodworking tools, but they have differences that make each one more suitable for one application than another. Either will get the job done. The traditional wood planer took the form of a wooden block with a blade on it that was used to shave layers off of wooden boards, with the main purpose being to create a flat, smooth, and uniform layer. If you plan to finish the piece with polyurethane, make sure the sealer is compatible.  The belt sander is handy for a lot of things but getting things strictly flat isn't it's top use for me. i have done it before and a router sled is the best way if you dont have access to a wide belt sander in some cabinet shop nearby. OK I'm new here, this is something I've dealt with many times.

The belt sander is handy for a lot of things but getting things strictly flat isn't it's top use for me. i have done it before and a router sled is the best way if you dont have access to a wide belt sander in some cabinet shop nearby. OK I'm new here, this is something I've dealt with many times.  As the wood passes by the blades, a certain amount of wood is uniformly removed from one side to the other, thus resulting in a perfectly flat and symmetrical board from front to back.

As the wood passes by the blades, a certain amount of wood is uniformly removed from one side to the other, thus resulting in a perfectly flat and symmetrical board from front to back.

My dinner table slab is about 4 foot by 6 foot. I'll report back on how my plane choice worked out after I have completed the jobif I still have strength in my arms to type.  On old blades, sometimes the corner is broken off. The cast iron will serve as a heat sink and quickly absorb the heat from the blade. JavaScript is disabled. After my experiences building cabinets, for cabinets and furniture youll want a sander with at least a 32 reversible capacity. Whether youre looking to rapidly remove stock or apply a finish, weve got the abrasive belts to meet your needs. Its important to remember that these tools are different and its a lot like trying to compare apples to oranges. With the edge squared, move to the bevel. Apply the wood conditioner. The jointer is working out well except that this board is ridiculously out-of-flat, which I should have anticipated better. Using light to make your object look just right is both art and science, so we found a pro who can break it down for you: McKay Nilson. In other words, you just have to hold the wood steady, and the planer does the rest of the work. Generally I just go one direction, but do whatever feels most natural. To determine if the surface is ready for the color coat, wet a clean rag with alcohol or lacquer thinner. Set the table of the sander perpendicular to the belt and grind the edge square. However, if you are looking to create curves, to smooth out a surface, to remove rough edges, to prepare a surface for painting, or to even out a small surface, then its a belt sander that you need. We will remove imperfections in grinding when we get to the honing stage. After smoothing the stained wood, apply a sealer coat of thinned shellac, sanding sealer, or other appropriate sealer. Covers Large Surface Areas: wide belt sanders can be used on bigger surface areas, reducing the time needed to complete a job. Once youre done, all you need to do is to apply a wood stain or paint the sanded edge of the door. Otherwise, it may interfere with paint adhesion. Do you still need to sand after using a planer? Wide belt sanders are ideal for smoothing out surfaces and rough edges, removing imperfections, and stripping away paint, lacquer, and stains. Give the director of marketing a hand plane and a ask him to do it .

On old blades, sometimes the corner is broken off. The cast iron will serve as a heat sink and quickly absorb the heat from the blade. JavaScript is disabled. After my experiences building cabinets, for cabinets and furniture youll want a sander with at least a 32 reversible capacity. Whether youre looking to rapidly remove stock or apply a finish, weve got the abrasive belts to meet your needs. Its important to remember that these tools are different and its a lot like trying to compare apples to oranges. With the edge squared, move to the bevel. Apply the wood conditioner. The jointer is working out well except that this board is ridiculously out-of-flat, which I should have anticipated better. Using light to make your object look just right is both art and science, so we found a pro who can break it down for you: McKay Nilson. In other words, you just have to hold the wood steady, and the planer does the rest of the work. Generally I just go one direction, but do whatever feels most natural. To determine if the surface is ready for the color coat, wet a clean rag with alcohol or lacquer thinner. Set the table of the sander perpendicular to the belt and grind the edge square. However, if you are looking to create curves, to smooth out a surface, to remove rough edges, to prepare a surface for painting, or to even out a small surface, then its a belt sander that you need. We will remove imperfections in grinding when we get to the honing stage. After smoothing the stained wood, apply a sealer coat of thinned shellac, sanding sealer, or other appropriate sealer. Covers Large Surface Areas: wide belt sanders can be used on bigger surface areas, reducing the time needed to complete a job. Once youre done, all you need to do is to apply a wood stain or paint the sanded edge of the door. Otherwise, it may interfere with paint adhesion. Do you still need to sand after using a planer? Wide belt sanders are ideal for smoothing out surfaces and rough edges, removing imperfections, and stripping away paint, lacquer, and stains. Give the director of marketing a hand plane and a ask him to do it .

There are then also small wheels or rollers that pull the wood over the platform and through the blades (the blades are on top, not the bottom). Unlike belt sanders, whose cutting ability can depend on how you hold the tool, planers dont need perfectly uniform passes to create an even surface. Especially if I had to square the blade above, I want to make sure you get an edge with no flat left. ___________________________________________________. What do you wipe wood with after sanding? Now that we know what a belt sander is, lets find out what a planer is. Shannon Rogers started woodworking by trying to build a proton pack, and has been in love with the craft ever since. If the slabs are not warped a sharp plane should make short work of mill marks. There are certain jobs where a wide belt sander makes more sense and it can be worth the additional investment. Taking a second to catch my breath. Call us today at (402) 867-6990 or fill out our form to learn more about our repair services. This field is for validation purposes and should be left unchanged. Whether youre looking to rapidly remove stock or apply a finish, weve got the abrasive belts to meet your needs. Then stupid hand tool freak Director of Marketing had to open his big mouth and suggest that "handplaning it would probably be faster and more precise." 2019 FINTECH ABRASIVES (FINISHING TECHNOLOGIES INC.), Open Coat Aluminum Oxide (Wood) Sanding Belts, Closed Coat Aluminum Oxide (Metal) Sanding Belts, Flexible Closed Coat Aluminum Oxide (Metal) Sanding Belts, Flexible Open Coat Aluminum Oxide (Wood) Sanding Belts, Hook and Loop Wet Dry Sharpening Film Discs, Hook and Loop Auto Paint and Finish Discs, Open Coat Aluminum Oxide (Wood) Sanding Discs, Closed Coat Aluminum Oxide (Metal) Sanding Discs, Surface Conditioning (non-woven) Sanding Discs, Open Coat Aluminum Oxide (Wood) Sanding Rolls, Sanding Sheets For Plastics and Composites, If youre working on a project that requires you to remove wood or caked-on varnish from a surface, you may be wondering whether you should use a wide belt sander or a planer.