pipe support shoe drawing engineering cpa 3d pipesupports Axial width of saddle support: b 1. Design Calculations Deisohexanizer Reboiler E-610 29 July 2010 Revision : 0 Ref. A common way to support piping in a plant is to use a pipe saddle to transfer the vertical load from a piece of pipe to another. This is common when installing piping directly above another piece of pipe or when retrofitting pipe in a facility. This design is used when access to pouring a pipe support within the foundation is not possible. 'Sample Piping Stress Analysis Calculations & Pipe Support

PDF Steel PipeA Guide for Design and Installation Piping Support: Types, Purpose, Design, Codes Local stress calculator for saddle supports and bare supported pipes. One of the most commonly used is the LeMond method, named after the American Tour de France champ . Components used in pipe supports, (rods, u

PDF Steel PipeA Guide for Design and Installation Piping Support: Types, Purpose, Design, Codes Local stress calculator for saddle supports and bare supported pipes. One of the most commonly used is the LeMond method, named after the American Tour de France champ . Components used in pipe supports, (rods, u

pipe saddle support design calculation - vssraipur.com

Fig. Material CS, SS, Coper etc. were to be completed within a reasonable time, we Design of pipe supports for Salem is in accor-dance with ANSI B31.1. pipe saddle  1 2 5 10.

1 2 5 10.

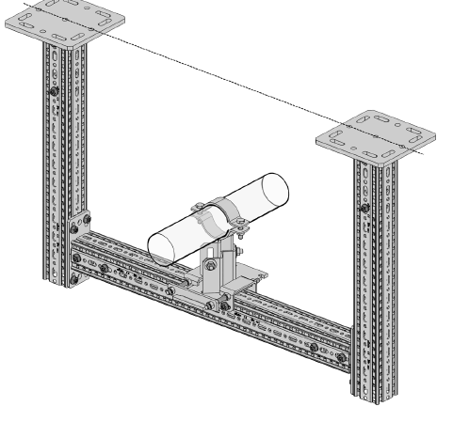

The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions. Project Data. Saddle Support Calculation Three-Bolt Pipe Clamp.

The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions. Project Data. Saddle Support Calculation Three-Bolt Pipe Clamp.

Pipe Supports, Guides, Shields & Saddles - Eaton

pipe saddle support design calculation - domzdravljapale.org PS-F - Heavy Duty Pipe Support - Flange Mount.

Nearby structural support. The pipe line is firmly anchored at both ends - one ends is anchored in the foundations of the intake and the other in the foundations of the power house. 1 2.

Q - Can you design a saddle with no clearance between the wear plate and the base A . 259 - Pipe Saddle Support with U-Bolt.

multiple locations allowing you to get the most less latency time to download any of our books like this one Saddle Support Calculation beta fbcport org Pipe Insulation Support Saddles Insulation Outlook April 21st, 2019 - For this application insulated saddles should always have a heavy gauge steel 12 gauge minimum support saddle plus a structural steel support plate 1 4 We serve the energy sectors such as oil & Engineering & Design of Pipe Supports While deciding proper pipe support spacing following shall be considered. Skirt support design calculation Camba.

Pipe Notching Calculator with Printable Templates

stanier (Mechanical) 19 Jan 11 22:34. Design Calculations Deisohexanizer Reboiler E-610 29 July 2010 Revision : 0 Ref.

OR1ONiAL This calculation verifies pipe support. Saddle design spreadsheet. Adjustable Pipe Saddle Support Adjuster is machined from solid steel - Not a modified cast iron reducer.

Sam Holdren says: October 7, 2020 at 3:03 am. 250. mm: As considered: Thickness of Shell Plate: t: 5. mm: A factor: K 5. Pipe Support Calculation

Material: Carbon steel with malleable iron reducer.

Material: Carbon steel with malleable iron reducer.

Design Code : AD-MERKBLAETTER 2000 (11-2007) Karman Effects Prevented by 3 Helicoidal Plates at 120 : no Calculation Sheets - calcstress This is a support article for our Saddle Support Design module. Conservative assumptions, along with an explicit safety factor, have been employed to assure a conservative design with an adequate overall safety factor. I want more details for manual calculation for pipe stress or force calculation. Saddles are formed from either A516-70 or A633 grade E modified plate and provide structural reinforcement for pipes in need of strengthening. Installation Guide for

Reply. :J, - Ans: It depends on the friction factor input in the dialog of the saddles between the sliding saddles and the concrete or the plate under the sliding saddles. Pipes are led by the terrain either freely deposited, on concrete foundations above the terrain, or in the open trenches, and finally buried in trenches. Take about 30% of the weight applied at the bearing flange and calculate bending on the web from bottom of flange to height of the web. pipe rilco analysis support stress system piping hanger manufacturing company sizing feasibility cfd audits calculations prep process report clamps Determination of maximum span between pipe supports

Piping Support Design and Engineering | Piping Engineering

loop piping horbar Design Calculations Deisohexanizer Reboiler E-610 29 July 2010 Revision : 0 Ref. Calculation Sheets | calcstress

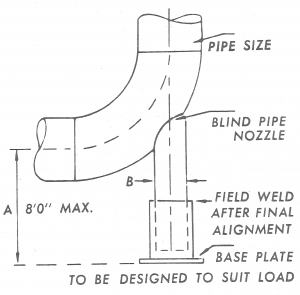

The three-bolt design allows the attachment to the pipe clamp outside of the insulation. Dimensions of pedestal.

Design Pipe Support Span (Spacing) Guideline - HardHat Engineer Threaded inserts are commonly installed in the top of the pipe support / sleepers allow for attachment of adjustable pipe saddle supports and couplings. Technology Business. Part #660Pipe Saddle Support. 1 - 25 of 32 | Results Per Page | View.

Piping Support: Types, Purpose, Design, Codes, Optimization Rules (PDF) Written by Anup Kumar Dey in Piping Stress Analysis, Piping Stress Basics. Local Stress in Support | calcstress calculator Design on Supports | DIPRA Pipe Saddle Support Calculations: Spreadsheet to select requisite polyiso insulation in a pipe saddle

Allowable stresses for A. Pipe Insulation Support Saddles - Insulation Outlook Magazine While checking the saddle calculation.

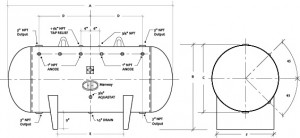

A complete set of piping drawings.

A complete set of piping drawings.

Email This Page Download PDF Printable Page. Div I and also is a basis for saddle support design in British Standard, BS-5500.

For designing the saddle support it is required to a calculate the thickness: Top flange, thickness (tf), Base thickness (tw), Stiffener thickness (ts), Web thickness (tb) PDF Pipe Supports, Guides, Shields & Saddles - Eaton Select diameter as , D =300 mm Flow velocity V = 4.Q / pi .D 22 = 5.9 m/s Renolds no = V.D x 10 66 Installation Guide for Pipe saddle and reinforcement pad.

Max. Project Data.

This pipe support spacing calculation was developed based upon equations contained in section 6.2 of Pipe Stress Engineering published by Peng Engineering. GENERAL 2.

Base can be cut to length in the field to a minimum height of 6". A properly designed pipe support span helps the piping design personnel to support pipes at regular spacings, thus reducing his work for unnecessary calculations. 1, shows the picture of a pipeline supported on two supports.

Stanchion type support for stationary pipe.

branch pipe reinforcement b31 asme calculator

Request Information Compare Items Search by Specification Add to CAD Cart.

Pipe end view diagram with wall thickness Print Tube Coping template at 100% printer scale, cut and wrap around cut tube to trace with marker pen for cutting and grinding to shape.

Piping Support: Types, Purpose, Design, Codes - What is Piping Plate Saddle.

Ans: It depends on the friction factor input in the dialog of the saddles between the sliding saddles and the concrete or the plate under the sliding saddles. MECHANICAL DESIGN CALCULATION The piping stress engineer is the party/person who is responsible for the engineering of these. Saddle Angle and Support Width Pipe supports should cradle the pipe in a saddle (see Figure 1).

Pipe support carries the pipe weight with contents.

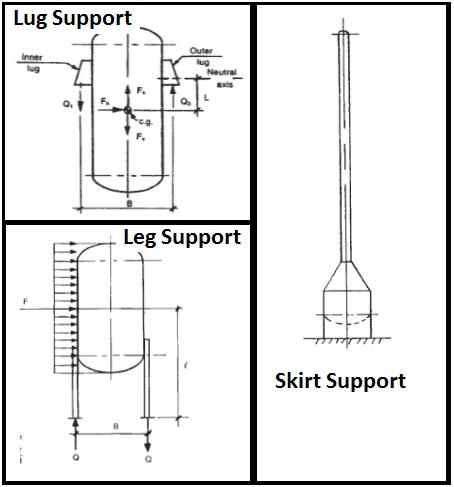

Total load coming on to the support = 63.8 KN. pressure vessel vessels supports types configuration typical general piping applications materials codes

Pipe Saddles and Supports The pipe diameter is 900mm and spacing is 7.50m. Dyplast Saddle Support Calculations for.

Request Information Compare Items Search by Specification Add to CAD Cart. conduit bends

pressure supports vessel types vessels type They can withstand pressures up to 900 psi.

Using CAESAR II and pipe stress calculations as per API, ASME B31.3, B31.1, B31.8, B31.4, CSA Z662. 9.1).

Figure 1. Pipe Saddle Support. Introduction to Pipe Supports

calculation horizontal vessels saddles stresses zick method located

Main Page; ISO-C1 Polyiso; ISO-HT Polyiso; EPS Insulation; About; Resources; Blog; Careers; Contact Us; Product Applications.

Main Page; ISO-C1 Polyiso; ISO-HT Polyiso; EPS Insulation; About; Resources; Blog; Careers; Contact Us; Product Applications.

Saddle Support Calculation Saddle Support Calculation fbcport org April 18th, 2019 - saddle support calculation is available in our book collection an online access to it is set as public so you can download it instantly Our book servers spans in design You will learn How Adjustable Pipe Saddle Support PHD Manufacturing 1 2.

This program is based on the equations and procedures found in the DIPRA brochure Design of Ductile Iron Pipe on Supports. No design is complete unless the engineer has had the opportunity to review the equivalent of the following project data: The pipe hanger specification, when available (A typical hanger specification is shown on pages 21 and 22).

Pipe Saddle Calculator. Pipe Support Spacing Calculation (Demo) - Pipeline Engineering

horisontal calculations Pipe Saddle Layout Calculator is a iPhone app that provides the fitter with the points to make an accurate cut (fish mouth, cope, etc) for piping (cylinder to cylinder) intersections. Stanchion type support with additional stability provided by U-bolt attachment to pipe. 258 - Pipe Saddle Support.

Steel piping on saddle supports - met-calc.com Step 2: Calculate the distance A using the below formula-. Insulation type, size, thickness. Pipe Saddle Calculations for Pipe Saddle Applications

The term engineered pipe supports relates to devices that are non-static, one-of-a-kind, location and condition specific. Pipe Saddle Calculations for Pipe Saddle Applications distance between supports with respect to considerations (b) & (c). 1.

Insuguard Pipe Saddle/Support.  Local stress calculator for saddle supports and bare supported pipes Interactive graphs which demonstrate local stress sensitivity to design parameters of the attachments.

Local stress calculator for saddle supports and bare supported pipes Interactive graphs which demonstrate local stress sensitivity to design parameters of the attachments.

pipe saddle support design calculation

DESIGN OF THE SUPPORT STRUCTURE FOR THE DESIGN OF PRESSURE VESSEL SADDLE AND ZICK ANALYSIS Hardware > Pipe Saddles & Supports >Part #660 Download Part #660 Data Sheet. Enter design variables for pipe system: outer diameter, pipe wall thickness, specific gravity if known, length between supports and shield arc shown in green cells: B13,14,16,18,19,20,21,22 according to the design of the system - Use Pipe Chart Dimensions & Weights-example 40s & Std 3. support vessel saddle pressure calculations mechanical horisontal Structural Support Design Guidelines - Fermilab Saddle Support Calculation - Paris Saint-Germain F.C. 1 - 25 of 32 | Results Per Page | View. Design Code : AD-MERKBLAETTER 2000 (11-2007) Karman Effects Prevented by 3 Helicoidal Plates at 120 : no with calculations and detailing of the pipe supports.

ductile iron, cast iron, etc. Piping support design, piping support design calculation ,Pipe Supporting, pipeline support, piping support, piping support types, types of pipe support, UES A leading consultant for ASME joint reviews and provider of engineering solutions on process engineering packages.

megachelon and design saddle spreadsheet!

pipe saddle support design calculation A pipe saddle is any pipe support that cradles a pipe and transfers the load of the piping system onto secondary members through its supporting base. For calculations on a 4-point stand, assume that the load is distributed on only 3 points. As mentioned early, this deformation causes a circumferential bending moment and direct tangential force in the shell.

Connect these fittings to thick-wall plastic pipe they have thicker, stronger walls than standard-wall fittings, so they can handle heavy duty industrial plumbing and water supply applications, such as water processing, waste water treatment, and irrigation.

Need Of Pipe Support The layout and design of piping and its supporting elements shall be directed toward preventing the following: (a) Piping stresses. Also it includes distributed circumferential moment and local stress for a bare supported pipe 21. Saddles - Calculation of the horizontal longitudinal - Bentley Thick-Wall Plastic Pipe Fittings for Water. Design Code : AD-MERKBLAETTER 2000 (11-2007) Karman Effects Prevented by 3 Helicoidal Plates at 120 : no Thick-Wall Plastic Pipe Fittings for Water. Pipe Saddle Support CHAPTER 9: Supports for Pipe - JSTOR