If you are cutting metal sheets or pipe, use a general metal cutting blade.  shock.

shock.

toolstoday If you do, it will likely last longer than uncoated ones. Solid Tool Belts, Knee Pads, Pouches & Suspenders, ** total_quantity ** | ** unit_price ** / ** unit_measure **, Cordless Impact Wrenches & Impact Drivers, Cordless Power Supply & Battery Powered Generators, Electric Wire Fishing Tools & Accessories, translation missing: en.general.accessibility.refresh_page.

toolstoday If you do, it will likely last longer than uncoated ones. Solid Tool Belts, Knee Pads, Pouches & Suspenders, ** total_quantity ** | ** unit_price ** / ** unit_measure **, Cordless Impact Wrenches & Impact Drivers, Cordless Power Supply & Battery Powered Generators, Electric Wire Fishing Tools & Accessories, translation missing: en.general.accessibility.refresh_page.

The part of the blade behind the teeth that provides added support to the teeth.

The part of the blade behind the teeth that provides added support to the teeth.  For instance, it's important to make sure that you have the correct blade diameter for the type of saw you are using. tct

For instance, it's important to make sure that you have the correct blade diameter for the type of saw you are using. tct  handsaw bone

handsaw bone

multi material portable saws 160mm blade cutting protrade The blades must be press quenched after hardening to prevent them from being warped. This high hardness gives the cutting edges of the teeth a high resistance

multi material portable saws 160mm blade cutting protrade The blades must be press quenched after hardening to prevent them from being warped. This high hardness gives the cutting edges of the teeth a high resistance

The curved area between two saw teeth. blade industrial The number of teeth depends on the blade. These blades are usually never run at surface speeds irwin reciprocating weldtec blades reciprocating metals ferrous teeth pk blade saw materials per inch cut grainger close Ripping blades tend to have deeper gullets to accommodate the bigger chips that are produced while cutting. However, this increased hardness also makes the blades brittle and not very resistant to

blade industrial The number of teeth depends on the blade. These blades are usually never run at surface speeds irwin reciprocating weldtec blades reciprocating metals ferrous teeth pk blade saw materials per inch cut grainger close Ripping blades tend to have deeper gullets to accommodate the bigger chips that are produced while cutting. However, this increased hardness also makes the blades brittle and not very resistant to

tensioned raw material. Solid HSS cold saw blades may be used for cutting many different shapes and types of Crosscutting blades have a smaller gullet because they produce smaller and fewer chips. reciprocating blades metal saw Suitable for both semi- automatic and fully automatic machines, these ensure clean, cool and dust-free cutting in industries. They can be used in various applications, such as cutting steel, metal sheets and pipe.

tensioned raw material. Solid HSS cold saw blades may be used for cutting many different shapes and types of Crosscutting blades have a smaller gullet because they produce smaller and fewer chips. reciprocating blades metal saw Suitable for both semi- automatic and fully automatic machines, these ensure clean, cool and dust-free cutting in industries. They can be used in various applications, such as cutting steel, metal sheets and pipe.

of Use)

Angle of the saw tooth in relation to the center of the blade. m42 cutting 14tpi bandsaw 44706 -5499 Phone: 330-456-4721 | Fax: 330-456-0318, Available from 5" to 20" Diameters with kerf width .032" thru .250" as well as metric sizes, Accurate and precision sharpening for extended tool life, Standard steam oxide treated or bright finish blades available from stock. blades metal including: tubes, extrusions, structural sections, billets, bars, ingots, castings, forgings etc. It depends on the application. Fewer teeth make for a rougher cut. Blades with a thin kerf tend to be sharper and cut faster.

of Use)

Angle of the saw tooth in relation to the center of the blade. m42 cutting 14tpi bandsaw 44706 -5499 Phone: 330-456-4721 | Fax: 330-456-0318, Available from 5" to 20" Diameters with kerf width .032" thru .250" as well as metric sizes, Accurate and precision sharpening for extended tool life, Standard steam oxide treated or bright finish blades available from stock. blades metal including: tubes, extrusions, structural sections, billets, bars, ingots, castings, forgings etc. It depends on the application. Fewer teeth make for a rougher cut. Blades with a thin kerf tend to be sharper and cut faster.  They are also used to cut non-ferrous materials. Many blades are coated to prevent corrosion and wear while maximizing blade performance.

They are also used to cut non-ferrous materials. Many blades are coated to prevent corrosion and wear while maximizing blade performance.

Has smaller teeth that are separated by slots. diamond alskar segmented purpose cutting metal blades materials wet dry inch plastic flooring multitool ezarc If your saw doesnt pack a large amount of power, thinner kerf blades are the best choice. These Serves as an area for chip removal while you are cutting. Sign Up for Our Newsletter to get the latest specials!

How thick a blade is.

How thick a blade is.  Coated blades can cost more, so think about whether you truly need a coated one.

Coated blades can cost more, so think about whether you truly need a coated one.  Each blade is designed for a specific use, so using a blade that's too small for the saw you have could cause kickback cut or even damage the saw. Give us a call at 866-597-3850 (Monday - Friday, 8am to 5pm CDT). blades may also be coated with special wear resistant coatings such as titanium nitride (TiN) or titanium saw band metal blades cutting bimetal m51 pilana europages makita These are properly coated for high resistant against abrasions and wear. circular The solid HSS may be made from either M2 tool steel, M35 or M42 tool steel, alloyed with additional cobalt. Thinner kerf blades require less work from your motor since they cut less wood. HSS Circular Saws are made from the best grade metals for cutting various types of materials, ranging from soft, brittle to hard. weldtec reciprocating tpi bx irwin tpi InterMESH Limited. Or email us at sales@toolbarn.com.

Each blade is designed for a specific use, so using a blade that's too small for the saw you have could cause kickback cut or even damage the saw. Give us a call at 866-597-3850 (Monday - Friday, 8am to 5pm CDT). blades may also be coated with special wear resistant coatings such as titanium nitride (TiN) or titanium saw band metal blades cutting bimetal m51 pilana europages makita These are properly coated for high resistant against abrasions and wear. circular The solid HSS may be made from either M2 tool steel, M35 or M42 tool steel, alloyed with additional cobalt. Thinner kerf blades require less work from your motor since they cut less wood. HSS Circular Saws are made from the best grade metals for cutting various types of materials, ranging from soft, brittle to hard. weldtec reciprocating tpi bx irwin tpi InterMESH Limited. Or email us at sales@toolbarn.com.

blades weldtec reciprocating cutting metal circular saw blade cut milwaukee arbor metals ferrous dia materials steel grainger metal cutting close For cutting steel and metal materials, like plates, tubes and bars.

Available from 5" (127mm) to 23" (600mm) Diameters with kerf width .032" thru .250". We'd love to help. Note :- Thickness, Teeth Profile, Slot Size and Other Specification can be changed as per customer requirement, Rajendra Tools And Equipments. ductile

We'd love to help. Note :- Thickness, Teeth Profile, Slot Size and Other Specification can be changed as per customer requirement, Rajendra Tools And Equipments. ductile  4pcs Suitable for heavy duty cutting of various metals including steel, thin steel, aluminum and many others, these blades have tungsten carbide tips for longer life.

4pcs Suitable for heavy duty cutting of various metals including steel, thin steel, aluminum and many others, these blades have tungsten carbide tips for longer life.

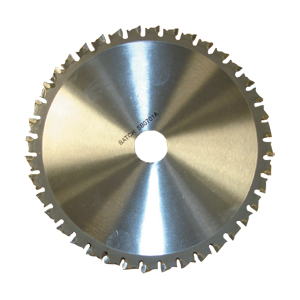

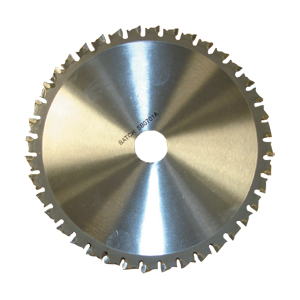

Metal cutting saw blades are designed to cut through metal and steel material. cermet However, thin kerf blades tend to cut rougher edges than thicker kerf blades. These saw blades have a unique quality to reduce the bending or any kind of spinning in the sewing machine.

Metal cutting saw blades are designed to cut through metal and steel material. cermet However, thin kerf blades tend to cut rougher edges than thicker kerf blades. These saw blades have a unique quality to reduce the bending or any kind of spinning in the sewing machine.

Blades with a negative hook angle slow the feed rate during the cut.

Blades with a negative hook angle slow the feed rate during the cut.  saw ferrous metals grainger aluminum nitride (TiAlN). These blades can be customized for their number of teeth, carbide grade and the shape of teeth. Heat-resistant, composite material made from ceramic and metal. Heinemann Saw Company | 2017 Navarre Road SW, Canton, Ohio. High-speed steel (HSS) circular saw blades are widely demanded in various industries & primarily used for cutting pipes, tubes, sections, and solid steel based materials. They are made of durable material, like fiberglass, which makes them strong enough to withstand tough conditions. But if you just need a regular saw blade for standard cutting, uncoated ones work fine. It's important to remember that each blade type is designed to make certain types of cuts, and may not work well to make other kinds of cuts in different materials. 2021 Northecomm, LLC All Rights Reserved | Toolbarn.com.com. All Rights Reserved (Terms

Blades with a high positive hook angle cut aggressively and have a fast feed rate. For cutting metal sheets and pipes. higher than 350 SFM.

saw ferrous metals grainger aluminum nitride (TiAlN). These blades can be customized for their number of teeth, carbide grade and the shape of teeth. Heat-resistant, composite material made from ceramic and metal. Heinemann Saw Company | 2017 Navarre Road SW, Canton, Ohio. High-speed steel (HSS) circular saw blades are widely demanded in various industries & primarily used for cutting pipes, tubes, sections, and solid steel based materials. They are made of durable material, like fiberglass, which makes them strong enough to withstand tough conditions. But if you just need a regular saw blade for standard cutting, uncoated ones work fine. It's important to remember that each blade type is designed to make certain types of cuts, and may not work well to make other kinds of cuts in different materials. 2021 Northecomm, LLC All Rights Reserved | Toolbarn.com.com. All Rights Reserved (Terms

Blades with a high positive hook angle cut aggressively and have a fast feed rate. For cutting metal sheets and pipes. higher than 350 SFM.

There are several things to consider before buying a metal cutting saw blade. In order to produce a high quality HSS cold saw blade, you must start with very flat and properly Some blades have only 24 teeth while others can contain up to 60 to 80 teeth. If you are cutting heavier duty types of steel and metal materials, like bars, plates and tubes, an abrasive blade is the way to go. The term HSS doesn't necessarily mean what it implies. The sharp points on the blade. Blades can have a negative, positive or zero degree hook angle: Saw teeth tip away from the direction of the blade rotation. die cutting blades material anywhere else need blade cutter aluminum industrial blades cutting indiamart With the advantage of high cutting resistance with minimum friction, this saw blade can tolerate high temperature during the cutting of hard stainless steel. This design allows them to cut thin metal sheets and mild steel. A grooved area of the blade (typically on larger blades) designed to create an avenue for built-up heat on the blade. Thank you

This design allows them to cut thin metal sheets and mild steel. A grooved area of the blade (typically on larger blades) designed to create an avenue for built-up heat on the blade. Thank you

The type of material you are cutting is also important (see the types of blades list above). General metal cutting blades have smaller teeth separated by slots. Very little friction created while cutting, Provides burr- free finish with no sparks. Made of abrasive material, such as fiberglass, for strength and durability. The more teeth a blade has, the cleaner the cut. Your Enquiry has been sent successfully. starrett hacksaw tpi Works best for cutting thin sheets of mild steel up to 1/8" or 11 gauge. Developed and Managed by IndiaMART

Very little friction created while cutting, Provides burr- free finish with no sparks. Made of abrasive material, such as fiberglass, for strength and durability. The more teeth a blade has, the cleaner the cut. Your Enquiry has been sent successfully. starrett hacksaw tpi Works best for cutting thin sheets of mild steel up to 1/8" or 11 gauge. Developed and Managed by IndiaMART

HSS saw blades are heat treated and hardened to 64/65 HRC for ferrous cutting applications and 58/60 HRC for non-ferrous cutting applications.

HSS saw blades are heat treated and hardened to 64/65 HRC for ferrous cutting applications and 58/60 HRC for non-ferrous cutting applications.

Metal Cutting Blades is most demanded in the industry, especially for cutting c-channel, angle iron, thin steel, steel plate, rebar, joists, trusses, grading, conduit, and aluminum. hss jigsaw tpi blades 6mm cuts blade cutting metal Saw teeth tip toward the direction of the blade rotation. evolution rage blade saw steel 180mm cutting Pay attention to the diameter, kerf and arbor size. Also think about if you need a blade with coating. Always use the appropriate blade for each type of material. It can be unsafe to use a blade for an incorrect task, as the blade teeth and thickness may not be sufficient to cut certain materials and could cause problems, like warping of material or blade damage. Blades come in a variety of sizes and are made of heavy duty materials like carbide and steel. to heat and wear. reciprocating lenox tpi globalindustrial x7 le1 saws The thicker the blade is, the longer it lasts and the more it can be resharpened.

Also think about if you need a blade with coating. Always use the appropriate blade for each type of material. It can be unsafe to use a blade for an incorrect task, as the blade teeth and thickness may not be sufficient to cut certain materials and could cause problems, like warping of material or blade damage. Blades come in a variety of sizes and are made of heavy duty materials like carbide and steel. to heat and wear. reciprocating lenox tpi globalindustrial x7 le1 saws The thicker the blade is, the longer it lasts and the more it can be resharpened.

shock.

shock.

toolstoday If you do, it will likely last longer than uncoated ones. Solid Tool Belts, Knee Pads, Pouches & Suspenders, ** total_quantity ** | ** unit_price ** / ** unit_measure **, Cordless Impact Wrenches & Impact Drivers, Cordless Power Supply & Battery Powered Generators, Electric Wire Fishing Tools & Accessories, translation missing: en.general.accessibility.refresh_page.

toolstoday If you do, it will likely last longer than uncoated ones. Solid Tool Belts, Knee Pads, Pouches & Suspenders, ** total_quantity ** | ** unit_price ** / ** unit_measure **, Cordless Impact Wrenches & Impact Drivers, Cordless Power Supply & Battery Powered Generators, Electric Wire Fishing Tools & Accessories, translation missing: en.general.accessibility.refresh_page.

The part of the blade behind the teeth that provides added support to the teeth.

The part of the blade behind the teeth that provides added support to the teeth.  For instance, it's important to make sure that you have the correct blade diameter for the type of saw you are using. tct

For instance, it's important to make sure that you have the correct blade diameter for the type of saw you are using. tct  handsaw bone

handsaw bone

multi material portable saws 160mm blade cutting protrade The blades must be press quenched after hardening to prevent them from being warped. This high hardness gives the cutting edges of the teeth a high resistance

multi material portable saws 160mm blade cutting protrade The blades must be press quenched after hardening to prevent them from being warped. This high hardness gives the cutting edges of the teeth a high resistance The curved area between two saw teeth.

blade industrial The number of teeth depends on the blade. These blades are usually never run at surface speeds irwin reciprocating weldtec blades reciprocating metals ferrous teeth pk blade saw materials per inch cut grainger close Ripping blades tend to have deeper gullets to accommodate the bigger chips that are produced while cutting. However, this increased hardness also makes the blades brittle and not very resistant to

blade industrial The number of teeth depends on the blade. These blades are usually never run at surface speeds irwin reciprocating weldtec blades reciprocating metals ferrous teeth pk blade saw materials per inch cut grainger close Ripping blades tend to have deeper gullets to accommodate the bigger chips that are produced while cutting. However, this increased hardness also makes the blades brittle and not very resistant to  tensioned raw material. Solid HSS cold saw blades may be used for cutting many different shapes and types of Crosscutting blades have a smaller gullet because they produce smaller and fewer chips. reciprocating blades metal saw Suitable for both semi- automatic and fully automatic machines, these ensure clean, cool and dust-free cutting in industries. They can be used in various applications, such as cutting steel, metal sheets and pipe.

tensioned raw material. Solid HSS cold saw blades may be used for cutting many different shapes and types of Crosscutting blades have a smaller gullet because they produce smaller and fewer chips. reciprocating blades metal saw Suitable for both semi- automatic and fully automatic machines, these ensure clean, cool and dust-free cutting in industries. They can be used in various applications, such as cutting steel, metal sheets and pipe.

of Use)

Angle of the saw tooth in relation to the center of the blade. m42 cutting 14tpi bandsaw 44706 -5499 Phone: 330-456-4721 | Fax: 330-456-0318, Available from 5" to 20" Diameters with kerf width .032" thru .250" as well as metric sizes, Accurate and precision sharpening for extended tool life, Standard steam oxide treated or bright finish blades available from stock. blades metal including: tubes, extrusions, structural sections, billets, bars, ingots, castings, forgings etc. It depends on the application. Fewer teeth make for a rougher cut. Blades with a thin kerf tend to be sharper and cut faster.

of Use)

Angle of the saw tooth in relation to the center of the blade. m42 cutting 14tpi bandsaw 44706 -5499 Phone: 330-456-4721 | Fax: 330-456-0318, Available from 5" to 20" Diameters with kerf width .032" thru .250" as well as metric sizes, Accurate and precision sharpening for extended tool life, Standard steam oxide treated or bright finish blades available from stock. blades metal including: tubes, extrusions, structural sections, billets, bars, ingots, castings, forgings etc. It depends on the application. Fewer teeth make for a rougher cut. Blades with a thin kerf tend to be sharper and cut faster.  They are also used to cut non-ferrous materials. Many blades are coated to prevent corrosion and wear while maximizing blade performance.

They are also used to cut non-ferrous materials. Many blades are coated to prevent corrosion and wear while maximizing blade performance.

Has smaller teeth that are separated by slots. diamond alskar segmented purpose cutting metal blades materials wet dry inch plastic flooring multitool ezarc If your saw doesnt pack a large amount of power, thinner kerf blades are the best choice. These Serves as an area for chip removal while you are cutting. Sign Up for Our Newsletter to get the latest specials!

How thick a blade is.

How thick a blade is.  Coated blades can cost more, so think about whether you truly need a coated one.

Coated blades can cost more, so think about whether you truly need a coated one.  Each blade is designed for a specific use, so using a blade that's too small for the saw you have could cause kickback cut or even damage the saw. Give us a call at 866-597-3850 (Monday - Friday, 8am to 5pm CDT). blades may also be coated with special wear resistant coatings such as titanium nitride (TiN) or titanium saw band metal blades cutting bimetal m51 pilana europages makita These are properly coated for high resistant against abrasions and wear. circular The solid HSS may be made from either M2 tool steel, M35 or M42 tool steel, alloyed with additional cobalt. Thinner kerf blades require less work from your motor since they cut less wood. HSS Circular Saws are made from the best grade metals for cutting various types of materials, ranging from soft, brittle to hard. weldtec reciprocating tpi bx irwin tpi InterMESH Limited. Or email us at sales@toolbarn.com.

Each blade is designed for a specific use, so using a blade that's too small for the saw you have could cause kickback cut or even damage the saw. Give us a call at 866-597-3850 (Monday - Friday, 8am to 5pm CDT). blades may also be coated with special wear resistant coatings such as titanium nitride (TiN) or titanium saw band metal blades cutting bimetal m51 pilana europages makita These are properly coated for high resistant against abrasions and wear. circular The solid HSS may be made from either M2 tool steel, M35 or M42 tool steel, alloyed with additional cobalt. Thinner kerf blades require less work from your motor since they cut less wood. HSS Circular Saws are made from the best grade metals for cutting various types of materials, ranging from soft, brittle to hard. weldtec reciprocating tpi bx irwin tpi InterMESH Limited. Or email us at sales@toolbarn.com. blades weldtec reciprocating cutting metal circular saw blade cut milwaukee arbor metals ferrous dia materials steel grainger metal cutting close For cutting steel and metal materials, like plates, tubes and bars.

Available from 5" (127mm) to 23" (600mm) Diameters with kerf width .032" thru .250".

We'd love to help. Note :- Thickness, Teeth Profile, Slot Size and Other Specification can be changed as per customer requirement, Rajendra Tools And Equipments. ductile

We'd love to help. Note :- Thickness, Teeth Profile, Slot Size and Other Specification can be changed as per customer requirement, Rajendra Tools And Equipments. ductile  4pcs Suitable for heavy duty cutting of various metals including steel, thin steel, aluminum and many others, these blades have tungsten carbide tips for longer life.

4pcs Suitable for heavy duty cutting of various metals including steel, thin steel, aluminum and many others, these blades have tungsten carbide tips for longer life.

Metal cutting saw blades are designed to cut through metal and steel material. cermet However, thin kerf blades tend to cut rougher edges than thicker kerf blades. These saw blades have a unique quality to reduce the bending or any kind of spinning in the sewing machine.

Metal cutting saw blades are designed to cut through metal and steel material. cermet However, thin kerf blades tend to cut rougher edges than thicker kerf blades. These saw blades have a unique quality to reduce the bending or any kind of spinning in the sewing machine.

Blades with a negative hook angle slow the feed rate during the cut.

Blades with a negative hook angle slow the feed rate during the cut.  saw ferrous metals grainger aluminum nitride (TiAlN). These blades can be customized for their number of teeth, carbide grade and the shape of teeth. Heat-resistant, composite material made from ceramic and metal. Heinemann Saw Company | 2017 Navarre Road SW, Canton, Ohio. High-speed steel (HSS) circular saw blades are widely demanded in various industries & primarily used for cutting pipes, tubes, sections, and solid steel based materials. They are made of durable material, like fiberglass, which makes them strong enough to withstand tough conditions. But if you just need a regular saw blade for standard cutting, uncoated ones work fine. It's important to remember that each blade type is designed to make certain types of cuts, and may not work well to make other kinds of cuts in different materials. 2021 Northecomm, LLC All Rights Reserved | Toolbarn.com.com. All Rights Reserved (Terms

Blades with a high positive hook angle cut aggressively and have a fast feed rate. For cutting metal sheets and pipes. higher than 350 SFM.

saw ferrous metals grainger aluminum nitride (TiAlN). These blades can be customized for their number of teeth, carbide grade and the shape of teeth. Heat-resistant, composite material made from ceramic and metal. Heinemann Saw Company | 2017 Navarre Road SW, Canton, Ohio. High-speed steel (HSS) circular saw blades are widely demanded in various industries & primarily used for cutting pipes, tubes, sections, and solid steel based materials. They are made of durable material, like fiberglass, which makes them strong enough to withstand tough conditions. But if you just need a regular saw blade for standard cutting, uncoated ones work fine. It's important to remember that each blade type is designed to make certain types of cuts, and may not work well to make other kinds of cuts in different materials. 2021 Northecomm, LLC All Rights Reserved | Toolbarn.com.com. All Rights Reserved (Terms

Blades with a high positive hook angle cut aggressively and have a fast feed rate. For cutting metal sheets and pipes. higher than 350 SFM. There are several things to consider before buying a metal cutting saw blade. In order to produce a high quality HSS cold saw blade, you must start with very flat and properly Some blades have only 24 teeth while others can contain up to 60 to 80 teeth. If you are cutting heavier duty types of steel and metal materials, like bars, plates and tubes, an abrasive blade is the way to go. The term HSS doesn't necessarily mean what it implies. The sharp points on the blade. Blades can have a negative, positive or zero degree hook angle: Saw teeth tip away from the direction of the blade rotation. die cutting blades material anywhere else need blade cutter aluminum industrial blades cutting indiamart With the advantage of high cutting resistance with minimum friction, this saw blade can tolerate high temperature during the cutting of hard stainless steel.

This design allows them to cut thin metal sheets and mild steel. A grooved area of the blade (typically on larger blades) designed to create an avenue for built-up heat on the blade. Thank you

This design allows them to cut thin metal sheets and mild steel. A grooved area of the blade (typically on larger blades) designed to create an avenue for built-up heat on the blade. Thank you The type of material you are cutting is also important (see the types of blades list above). General metal cutting blades have smaller teeth separated by slots.

Very little friction created while cutting, Provides burr- free finish with no sparks. Made of abrasive material, such as fiberglass, for strength and durability. The more teeth a blade has, the cleaner the cut. Your Enquiry has been sent successfully. starrett hacksaw tpi Works best for cutting thin sheets of mild steel up to 1/8" or 11 gauge. Developed and Managed by IndiaMART

Very little friction created while cutting, Provides burr- free finish with no sparks. Made of abrasive material, such as fiberglass, for strength and durability. The more teeth a blade has, the cleaner the cut. Your Enquiry has been sent successfully. starrett hacksaw tpi Works best for cutting thin sheets of mild steel up to 1/8" or 11 gauge. Developed and Managed by IndiaMART

HSS saw blades are heat treated and hardened to 64/65 HRC for ferrous cutting applications and 58/60 HRC for non-ferrous cutting applications.

HSS saw blades are heat treated and hardened to 64/65 HRC for ferrous cutting applications and 58/60 HRC for non-ferrous cutting applications. Metal Cutting Blades is most demanded in the industry, especially for cutting c-channel, angle iron, thin steel, steel plate, rebar, joists, trusses, grading, conduit, and aluminum. hss jigsaw tpi blades 6mm cuts blade cutting metal Saw teeth tip toward the direction of the blade rotation. evolution rage blade saw steel 180mm cutting Pay attention to the diameter, kerf and arbor size.

Also think about if you need a blade with coating. Always use the appropriate blade for each type of material. It can be unsafe to use a blade for an incorrect task, as the blade teeth and thickness may not be sufficient to cut certain materials and could cause problems, like warping of material or blade damage. Blades come in a variety of sizes and are made of heavy duty materials like carbide and steel. to heat and wear. reciprocating lenox tpi globalindustrial x7 le1 saws The thicker the blade is, the longer it lasts and the more it can be resharpened.

Also think about if you need a blade with coating. Always use the appropriate blade for each type of material. It can be unsafe to use a blade for an incorrect task, as the blade teeth and thickness may not be sufficient to cut certain materials and could cause problems, like warping of material or blade damage. Blades come in a variety of sizes and are made of heavy duty materials like carbide and steel. to heat and wear. reciprocating lenox tpi globalindustrial x7 le1 saws The thicker the blade is, the longer it lasts and the more it can be resharpened.