KTV Group Nigeria is an ISO-certified company located in Nigeria, offering its expertise to the offshore and the land-based industry. Hot taps allow you to isolate pipelines for work like branch additions, maintenance, or repairs without interrupting service. Most oil and gas companies need to avoid disruption and outages at any cost. Cold taps could be used to safely check for or release unknown pressure or fluid in piping. A hot tap saddle, service saddle or welded threadolet, valve installed, assembly is pressure tested and hot tap machine attached.  You can trust our certified technicians for your critical infrastructure. 929 0 obj

<>

endobj

This completion plug is set below the valve, once set, pressure above the plug can be bled off, and the valve can then be removed. This means that a pipe or tank can continue to be in operation whilst maintenance or modifications are being done to it. 969 0 obj

<>stream

endstream

endobj

933 0 obj

<>stream

Hot Tap or Hot Tapping is a proprietary method for adding a branch connection to a hot or operating line. They do not, Seat valves, ball valves, and butterfly valves are the most common types of, Gate, globe, plug, ball, butterfly, check, diaphragm, pinch, pressure relief, What are the two basic types of relief valves? The existing pipe wall thickness (actual) needs to be at least equal to the required thickness for pressure plus a reasonable thickness allowance for welding.

You can trust our certified technicians for your critical infrastructure. 929 0 obj

<>

endobj

This completion plug is set below the valve, once set, pressure above the plug can be bled off, and the valve can then be removed. This means that a pipe or tank can continue to be in operation whilst maintenance or modifications are being done to it. 969 0 obj

<>stream

endstream

endobj

933 0 obj

<>stream

Hot Tap or Hot Tapping is a proprietary method for adding a branch connection to a hot or operating line. They do not, Seat valves, ball valves, and butterfly valves are the most common types of, Gate, globe, plug, ball, butterfly, check, diaphragm, pinch, pressure relief, What are the two basic types of relief valves? The existing pipe wall thickness (actual) needs to be at least equal to the required thickness for pressure plus a reasonable thickness allowance for welding.

Hot tapping, or pressure tapping, is the method of making a connection to existing piping or pressure vessels without the interrupting or emptying of that section of pipe or vessel. They may also be used to make piping connections where it would be inconvenient to prepare the system for hot work.

Most of these drawbacks come down to inherent safety risks of working with live pipelines. Hot andCold Tapping also refer to pressure tapping, is one of the technique to attach a branch connection to existing piping or pressure vessels while the system is in services. Onto this fitting, a valve is attached, and the hot tap machine is attached to the valve. Use tab to navigate through the menu items.

Generally, hot tapping is completed through the use of welding. Hot Taps or Hot Tapping is the ability to safely tie into a pressurized system, by drilling or cutting, while it is on stream and under pressure. Hot Taps shall be installed by trained and experienced crews. FYI I see a fair amount of "cold" connections being use these days, usually on low temp critical commodities fuel gas, vapor recovery headers, vacuum lines, exotic alloy pipe, etc. The cracking risk can be reduced by the use of low-hydrogen electrodes, and through careful selection of heat input. Coring We can core holes in pipe, plate or structural to ensure correct dimensions and retreveal of slug/core. The larger hole in the pipe, allows the line stop head to fit into the pipe. The process is also used to drain off pressurized casing fluids and add test points or various sensors such as temperature and pressure.

The line stop actuator is used to insert a plugging head into the pipe, the most common type being a pivot head mechanism.

Thank you very much Mr. Jop and Mr. 11echo. The KTV Groups QA and Environmental Management System has been certified pursuant to these standards: ISO 9001, ISO 14001 and OHSAS 18001. Cold Tapping is a term used to describe a method of tapping into a live tank, pipeline, tubing, or well casing without the need to do any welding or hot work. The hot tap cutter is attached to a cutter holder, with the pilot bit, and is attached to the working end of the hot tap machine, so that it fits into the inside of the tapping adapter. Line stops often utilize special Valves, called Sandwich Valves. If you have a two lever tap, the hot side has a valve and the cold side has a diverter. The pressure test is very important, so as to make sure that there are no structural problems with the fitting, and so that there are no leaks in the welds. There are several different types of completion flange/plug sets, but they all operate in basically the same manner, the completion plug and flange are manufactured, so as to allow the flange, to accept and lock into place, a completion plug. If you continue to use this site we will assume that you are happy with it. Image presentation Hot tapping and Line stopping. Tapping fittings like Weldolet, Reinforced Branch or Split Tee. Hln :3dB^C(N8[H@U$unf&K&bK-nx In tank cleaning, we make use of holes and openings to inject a cleaning medium. endstream endobj startxref The former requiring of a cold work permit (no welding) and the latter requiring of a hot work permit (welding required). These are "saddles" that are held in place with U-bolts, the branch connection on these saddles have a large/thick O-ring type gasket to seal this attachment, these tend to be on the smaller size (biggest I've seen is 4"). SINGAPORE | INDONESIA | MALAYSIA | ACMV| LEAK DETECTION | LEAK REPAIR | COMPOSITE REPAIR| HOT TAPPING | COLD TAPPING | PIPE FREEZING | INSULATION| PIPE WORKS | REINSTATEMENT WORKS. Hot tapping permit adding connections without depressurization or disruption of process operations. + T Qs22e8Vx0?bcw2`mUb*9. Extensive changes arent just more expensive, but they also have more potential failure points. Fax #: (318) 222-6185. endstream endobj 934 0 obj <>stream to gathering in-depth data about the pipeline and materials inside the pipe, this can take some time.

Substances which may undergo reaction or decomposition leading to a dangerous increase in pressure, explosion or attack on metal. hWmoF+qC_5k+h0[ The fitting/valve combination, is attached to the pipe, and is normally pressure tested. When you need specialty services, our team at Leverage Mechanical Services is here for you. This can expose people, equipment, and the environment to materials under high pressure. Cold Taps should always be used prior to cutting into any existing piping system. Hot tapping, also known as pressure tapping, is a method of connecting (either by drilling or cutting) to a pressurised system, such as a pipeline or pressure vessel, without removing the pipe or tank from service. This leads to shorter cooling times, with an associated increased risk of forming hard microstructures and thus greater susceptibility to hydrogen cracking. I've never seen or heard of this, and I'm having a hard time visualizing it. The tapping adapter will contain the pressure of the pipe system, while the pipe is being cut, it houses the cutter, and cutter holder, and bolts to the valve. Once the plug has been properly positioned, it is locked into place with the lock ring segments, this prevents plug movement, with the o-ring becoming the primary seal. Hot tapping is a method of making a new connection to an existing pressurized pipeline without interrupting flow or emptying the section of pipeline or vessel. We offer total service and support for your infrastructure, from equipment installation to field machining and rebuilds.

There are a few methods of tapping into live systems, but hot tapping is one of the most straightforward and consistent. The line stop actuator is operated, to push the plugging head (line stop head), down, into the pipe, the common pivot head, will pivot in the direction of the flow, and form a stop, thus stopping the flow in the pipe. Regardless, these are all terms for tapping into an active system; they simply differ with the exact process that is used. Hot tapping can still be dangerous, especially in a field that has to do with potentially harmful materials. In the welding context, it is commonly used for any welding onto in-service equipment. These are wires which run through the pilot bit, and are cut and bent, so that they can fold back against the bit, into a relief area milled into the bit, and then fold out, when the pilot bit has cut through the pipe. There must be cutting involved into the header, much like the removal of a hot tap coupon? Temper bead deposition sequences can be used to control hardness. Fittings such as hot tapsaddles and hot tapping tees are frequently used. Fluid is drained and hot tapping machine is removed.

a8-/$;Yw'k_f3xV~~|$CVyDm'5G-QA3Jz_dG7xh*%* QTFB`]yQQfQ:Q?)*{|2Kd'G0h4 k+LN9hg Ne7StHz%RiqjckjVuor^ J Image presentation of The Coupon, is the section of pipe that is removed, to establish service. The tapped valve is now ready for the contractor's tie-in or IFT's linestop/stopple equipment to be inserted.[3].

Pipeline hot tapping is also usually a more direct, simple response to maintenance or upgrade problems. New studs, nuts, and gaskets should be used on the final completion, when a blind flange is installed outside of the completion plug. Tank and confined space lighting for hazardous locations, Pipeline external and internal inspection and surface treatment, ISO 9001, ISO 14001 og OHSAS 18001 certified. %PDF-1.5 % This prevents costly and potentially dangerous environmental hazards while allowing for continued operation. Pressure is bled off from the inside of the Tapping Adapter, so that the hot tap machine can be removed from the line. Its also possible that the materials within the system will need to be contained. Pressure can also be alleviated, and fluids can be drained as needed, under a controlled system, rather than having to empty the entire pipeline or tank at once. Tapping saddles are ideal for service connections and provide an effective means of conducting an under pressure tapping. If the actual thickness is barely more than that required for pressure, then loss of containment at the weld pool is a risk. Thus, theres never anypossibility that a leak could occur. If youre interested in learning more about hot tapping, how its completed, and specialized equipment that reduces the risk of error, contact the experts at Steel Forgings today. Pipe Medium: Chilled Water, Hot Water, Condenser Water, Compressed Air, Fuel, Oil based solvent and etc. Pretect provide a comprehensive range of Pipeline Intervention services that allows plant or pipeline operators an alternative solution to costly shutdowns repair maintenance modifications, Onshore-offshore or Subsea, Pretect can deliver Pipeline Intervention services where the client needs them.

Burn-through occurs when welding onto a pressurised pipe if the unmelted area beneath the weld pool is not strong enough to contain the internal pressure of the pipe.

The coupon is normally retained on one or more u-wires, which are attached to the pilot bit. icb>HkfCZFDkfF=MP.a"5e>_$z7Mm# 5

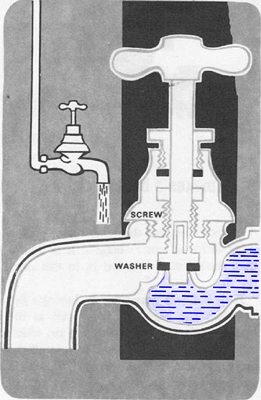

For a hot tap, there are three key components necessary to safely drill into a pipe; the fitting, the valve, and the hot tap machine. The materials inside the tank or pipe could react negatively to the heat it is being exposed to during the process of welding on the new conduit or cutting through the pipe; a critical temperature cannot be exceeded. Can Anyone Explain me About Hot Tapping and Cold Tapping? The testing medium should be selected based on the temperature of the fluid flowing through the pipeline / equipment. If on the saddle, are there two halves to the saddle and how would the seam be sealed? Hydrogen cracking is another issue that could occur during the hot tap process. Compressed air in the presence of hydrocarbons which may be present either in the air or deposited on the inside surfaces of the equipment or pipe. Coupon retention is mostly the "job" of the u-wires. Refer Fig. Therefore, its important to fully vet the team responsible for servicing your pipeline. This helps reduce disruptions to your processes and operations. New Orleans, 10-13 January 1988. p1-10. I still believe in respect. By keeping the plant or pipeline operational but also being able to undertake modifications or repairs allows maximum efficiency of plant with minimum disruption to loss or revenue. Finally, hot tapping improves upon worker safety, because workers are less likely to potentially be exposed to oil and gas within these pressurized systems. Its possible that burning-through could occur, or that the product could experience an unstable decomposition. The hot tap cutter, is a specialized type of hole saw, with a pilot bit in the middle, mounted inside of a hot tap adapter housing. We offer total service and support for your infrastructure, from equipment installation to, and rebuilds. This involves attaching the hot tap machine to the pipeline, typically through welding, bolting, or clamping. Theres significantly less downtime with hot taps compared to shutting down for pipeline work. Mechanical fittings may be used for making hot taps on pipelines and mains provided they are designed for the operating pressure of the pipeline or main, and are suitable for the purpose. Address: No 2c A.J Marinho Drive Off Sinari Daranijo Off Legali Ayorinde Victoria Island Lagos.