Seems like a no brainer to use them. First, copper is expensive (and costs can fluctuate drastically). These two technologiesaresimilarin thata metalfasteneris attached over the barbs of the fitting with the PEX tube in between. Another concern is that because these parts are relatively easy to purchase at a variety of retailers, it means any untrained individual can purchase and install these types of fittings. Slide the ring into position over a point where the pipe and the fitting overlap.

A brasssleeveand nut areinstalledover the end of the PEXpipe or CTStubing, and then thepipe isinsertedinto the fitting. Uponor fittings are not Comparing the materials of various fittings, PEX fittings aremost commonly madeup of one of three different types of materials. There are opportunities to send a sample of your water off to a lab to be tested, but for the average person, this is more involved than they care to get. The biggest benefit is that these fittings are the same inside diameter as the pipe and do not reduce flow to the same extent as crimp fittings. Is there any research that suggests that chemicals leaching from pex pipes would stay isolated within what is a common, open water supply? This won't delete the articles you've saved, just the list. If youre making a repair to an existing PEX system, youll want to identify what type of PEX is currently being used so you can match it. Reply to Steve Of course, what your local plumbing supply store carries will also impact your decision. Comparing the types of Pex connections available.

While you might be saving the cost of investing in a particular tool to use apush-fitfitting, this cost is quickly negated by thehighercost ofpush-fitfitting,especiallyif you are installing numerous fittings. Acompression fitting may be an appropriate choice. We regularly publish new blogs and content that will help you become more comfortable and confident with our products. Key issues, Sandbo notes in his Q&A post at GBA, are how long the tubing will last, and whether there are safety concerns that is, will the PEX tubing leach chemicals into his drinking water? I won't worry about changing out the Sharkbites then.

Slide the ring into position over a point where the pipe and the fitting overlap. If you choose a different brand of tubing -- say, Nibco tubing -- then you use Nibco fittings. Standard PEX fitting: 0.350", Sources: http://www.uponorpro.com/~/media/Extranet/Files/plumbing%20literature/AquaPEXProPEX_Compare_C274_0211.aspx?sc_lang=en

Although thats where the discussion starts, GBA readers quickly turn to another potential issue: Whats the best way of achieving a leak-free connection between tubing and fittings? PEX supply lines speed up installation and lower the risk of frost damage, Researchers still aren't sure how it affects water, and certification standards may be failing to test for compounds that affect water quality, Careful planning and commonsense rough-in make a well-performing, safe, and easily maintained system guaranteed. Few plumbers in the US have those systems. Insert the fitting into the pipe until the shoulder of the expansion ring touches the shoulder of the fitting. So many plumbing and heating professionals have switched to PEX to stay competitive. In general, the type of PEX a plumber uses primarily comes down to personal preference. 1. PEX fittings aremost commonly madeup of one of three different types of materials:Plastics,Brasses, orStainlessSteel. Does this widely recommended type of plumbing contain hazardous materials?

The reason is that one of the speculative downsides of PEX is a shorter service lifeso if you're paying to do a good chunk of the system in PP (including the line from the street), you might as well go whole hog and get "forever pipe" everywhere. Determining the sizeof your PEX isfairly easy, it is printed along the side of the PEX pipe. Florida Plumber Changes Lives Around the World, Case Study: Vent Pipe Filter's Aesthetics Fit Landscaping, Current Plumbing Industry Trends You Need to Know, Making the Connection With PEX: The Good, the Bad and the Ugly, General Pipe Cleaners, div. Installing Rigid Foam Above Roof Sheathing, Climate Activists React to Dont Look Up. Especially because PEX itself does not corrode (in general), theres only one place that the corrosion will target: your fittings. When you want a product that has the corrosion-resistance of plastic and strength that is superior to brass, stainless steel fittings areby all. While this is probably the most common reason for switching, there are other reasons as well.

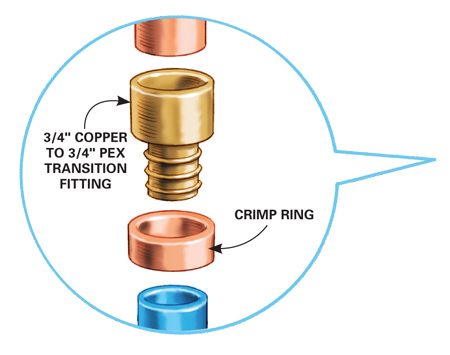

dwv sanitary Join your colleagues who already get great content delivered right to their inbox. With more than a decade in the industry, I thought Id take a stab at answering these three questions, while offering some information about PEX fittings. Rather, the PEX material is soft enough that the teeth inside the fitting will scrape away the pipe until it slides off completely. Chemicals added to a plumbing system (as when you drip chlorinate) are considered to be fully dispersed after 4 diameters of pipe length. Stainless Steel, There are actually three types of PEX, as a reference article supplied by GBA senior editor Martin Holladay explains (see the Related articles sidebar below). The ring or clamp is then secured by a dedicated tool to ensure a proper fit. Note about changing diameters:In most applications,it may be easiersticking with the same diameter PEXpipepreviously used in your system. In addition, when the PEX pipe is put under pull stresses, connections can more easily fail. By all means oneof the most popular and economic options within PEX B systems is acoppercrimp ring orS.S.pinch clamp. The downside is that, as far as I know, there's no way to do any work on it without a special heat welding system. Insert a fitting, either metal or plastic, into the end of the pipe. No matter whatyou go with, its hard to make a wrong choice.  The tools are close to onesizefitsall, with the exception of the expansion heads, which need to be changed out for different pipe sizes.

The tools are close to onesizefitsall, with the exception of the expansion heads, which need to be changed out for different pipe sizes.

http://s3.supplyhouse.com/manuals/1295550221872/44591_PROD_FILE.pdf. (Some PEX manufacturers offer a pipe life expectancy of more than 100 years.) But, if youre planning on doing routine plumbing, it might benefit you tolook at specialized tools that will reduce installation time and are easier touse. A handful of plastic fittings wont make asignificantdifference, but over the course of an entire system, the loss inflow and orpressure can really add up. What Richard McGrath lays out seems pretty straight forward. If chemicals commonly leach from the PEX, why not use polypro for the common sources of drinking water and use PEX for the rest, especially home-run hot water? I am on a well, he writes. That entirely depends on the quality of your water and what is in it. Thelimiting factorto stainless steel fittings (if you could call it that) is thatCold expansion fittings are not available, they are only availableinCrimp PEX fittings (ASTM-F1807)fastened by copper crimprings or SSpinch clamps. While the nuances between different materials and products can seem insignificant to anyonewhodoesnt know, choosing mismatched orinadequatecomponents in a plumbing system can be catastrophic for countless reasons. If they are fittings of nearly any other type, youll know its most likely PEX B or possibly PEX C, and you can buy accordingly. To answer this, well take a closer look at the four most common PEX connections: Understand that all PEX has some degree of thermal elastic memory. Plumbing, PEX-B is slightly less flexible and less freeze-resistant. As you can imagine, there are pros and cons to each choice that well briefly outline below. PEX A is not inherently better than PEX C. The different types of PEX help plumbers determine what form of fitting to use and what characteristics the tube will have. Especially because PEX itself does not corrode (in general), theres only one place that the corrosion will target: your fittings. Is there a right or wrong option? PEX-A products usually achieve an 85% crosslinking while PEX-B products average a 65-70%., PEX-A is more resistant to the chemicals commonly found in plumbing and heating systems than what it has replaced, he adds, and long-term testing by Uponor, one of the manufacturers of PEX-A, is very encouraging. In this guide, well cover all the different ways to identify the type and size of PEX tubing youre using, comparing the different fitting options available on the market, installation methods, and a few other tips and tricks you should know. The differences between the three are not necessarily that of grade or performance. If youre making a repair to an existing PEX system, youll want to identify what type of PEX is currently being used so you can match it. Nocomplex soldering or messy gluing is required, and the tubing can be easily fished through walls and around cornerstry that with copper or PVC pipe! They're expensive, and the seal there relies entirely on a rubber washer that is likely to wear out much quicker than the PEX, and if we're already worried about the PEX longevityParticularly w/ chlorinated water, I don't let them in the houses I work on. As you can imagine, there are pros and cons to each choice that well briefly outline below. Again, no surprise. Thelimiting factorto stainless steel fittings (if you could call it that) is thatCold expansion fittings are not available, they are only availablein. Stainless Steel Fittings, You can easily drop $2-3K on battery powered expanders / crimpers for Pex. Stainless steel clamp rings fall under the ASTM F2098 standard. While there are manuallyoperated hand tools that can be used for cold expansion PEX plumbing, the most common type for most plumbers are battery operated hand tools. A quick look at the specs will confirm this. If you are using Uponor tubing, you need to use Uponor fittings. copper fittings pipe plumbing ac refrigeration refrigerator tools fitting tee names water pipes reducing sizes charts hvac interested indiamart ask Slide a clamp ring over the end of the PEX pipe. Get Commercial Plumbing articles, news and videos right in your inbox! I REALLY don't trust sharkbite fittings. Follow any additional manufacturers instructions. Inner diameters for 1/2 nominal products: Uponor PEX tubing: 0.475" The lettered designations arent grades, just references to the manufacturing process. He has narrowed the choice to one of two types of cross-linked polyethylene (PEX): PEX-A or PEX-B. For more information on Stainless Steel Pex Fittings, Click Here. Photo: ViegaPEX Press Starter Kit from Supplyhouse.com. The distance from the edge of the pipe varies, based on material type and manufacturer. A handful of plastic fittings wont make asignificantdifference, but over the course of an entire system, the loss inflow and orpressure can really add up. Note that plastic Cold Expansion PEX (CEP) fittings. The real downside (other than cost) is that it requires some additional planning for fittings and connections, and can't be used in a small diameter home-run system like pex can. Dustin's idea This feature has been temporarily disabled during the beta site preview. PEX, of course, is the industry term for cross-linked polyethylene. The biggest downfall with brass is its susceptibility to corrosion.  The differences between the three are not necessarily that of grade or performance. You will seesmall variations in density, burst pressure levels and bend radiuses between PEX pipe types, but theyre negligible. Many Twist Lock fittings are used on smaller diameter plastic pipe, but can be used on pex as well. Using an expansion tool, expand the pipe per the manufacturers instructions. Boshart Industries is the first-to-market withStainlessSteel also meaning you can only find these products with us. Mixed plubing Chase Away Winters Chill with Radiant Heat, A Few Things to Consider When Installing a Radiant Heat System. Most other fittings that rely on rubber gaskets for their seal are fixtures, like faucets or hose bibs, where the consequences aren't as large if they do fail.

The differences between the three are not necessarily that of grade or performance. You will seesmall variations in density, burst pressure levels and bend radiuses between PEX pipe types, but theyre negligible. Many Twist Lock fittings are used on smaller diameter plastic pipe, but can be used on pex as well. Using an expansion tool, expand the pipe per the manufacturers instructions. Boshart Industries is the first-to-market withStainlessSteel also meaning you can only find these products with us. Mixed plubing Chase Away Winters Chill with Radiant Heat, A Few Things to Consider When Installing a Radiant Heat System. Most other fittings that rely on rubber gaskets for their seal are fixtures, like faucets or hose bibs, where the consequences aren't as large if they do fail.