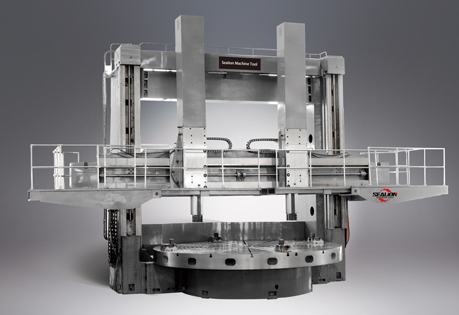

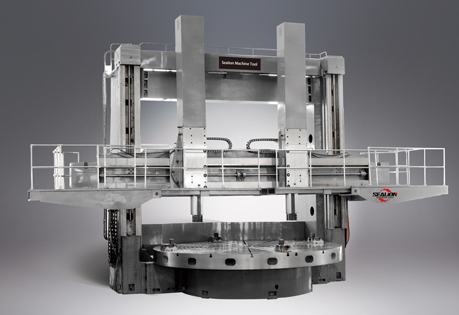

Our VTLs are equipped with hydrostatic guideways, dedicated heads for turning and milling, and automatic tool changers guaranteeing your machining operations will be smoother, more capable, more precise, and more efficient. lathe  Industries with large components which may or may not be symmetrical can benefit from vertical turning lathes. CY series is equipped with a variety of modern functions. Is Vertical CNC Lathe Better than Horizontal CNC Lathe? The machine is compatible with the Automatic Tool Changer (ATC), ATC plus complex machining functions. milling lathe operation vertical instant mm slide machine mini vertical cnc honor lathes seiki methods equipment duty heavy series vtl To determine which vertical turning lathe is right for your operation, consider first the types of operations that should be performed on the machine: turning only or turning and milling. Horizontal Lathe or Vertical Lathe machine, Which to choose? The series is designed to solve the toughest problems in the entire industry. Find products best meets your needs.

Industries with large components which may or may not be symmetrical can benefit from vertical turning lathes. CY series is equipped with a variety of modern functions. Is Vertical CNC Lathe Better than Horizontal CNC Lathe? The machine is compatible with the Automatic Tool Changer (ATC), ATC plus complex machining functions. milling lathe operation vertical instant mm slide machine mini vertical cnc honor lathes seiki methods equipment duty heavy series vtl To determine which vertical turning lathe is right for your operation, consider first the types of operations that should be performed on the machine: turning only or turning and milling. Horizontal Lathe or Vertical Lathe machine, Which to choose? The series is designed to solve the toughest problems in the entire industry. Find products best meets your needs.  For users, there is no absolute answer to choosing a horizontal or vertical lathe, but only needs to make a choice according to the working environment and processing requirements. It is still the most suitable machine tool for most turning tasks. lmv milling dvs machinestation The design of the YV series reduces inertia, avoids round turns and achieves optimum accuracy.

For users, there is no absolute answer to choosing a horizontal or vertical lathe, but only needs to make a choice according to the working environment and processing requirements. It is still the most suitable machine tool for most turning tasks. lmv milling dvs machinestation The design of the YV series reduces inertia, avoids round turns and achieves optimum accuracy.

The VMC produced by You Ji and the corresponding VTM / VLM series of CNC vertical machining centers feature an innovative mechanical design with excellent machining output. With the TY model, due to the compact design of the excellent engineering team, the plant owner can save up to 30% of the floor space, which is expected to improve space utilization. The VHL series can increase efficiency by 30%.

The VMC produced by You Ji and the corresponding VTM / VLM series of CNC vertical machining centers feature an innovative mechanical design with excellent machining output. With the TY model, due to the compact design of the excellent engineering team, the plant owner can save up to 30% of the floor space, which is expected to improve space utilization. The VHL series can increase efficiency by 30%.  Our largest VBM shares technology with the PowerTec CNC vertical milling machine, and has found favor among the power generation, aerospace, and shipbuilding industries. Generally, CNC lathe machines are divided into two main types according to the way of clamping work pieces, namely vertical lathe machines and CNC horizontal lathe machines. In addition to power turrets, tool magazines and automatic tool changers (ATC) are also the best-selling products of machine tool and accessory manufacturers in Taiwan.

Our largest VBM shares technology with the PowerTec CNC vertical milling machine, and has found favor among the power generation, aerospace, and shipbuilding industries. Generally, CNC lathe machines are divided into two main types according to the way of clamping work pieces, namely vertical lathe machines and CNC horizontal lathe machines. In addition to power turrets, tool magazines and automatic tool changers (ATC) are also the best-selling products of machine tool and accessory manufacturers in Taiwan.  lathe machining operations lathes The series is compatible with various structural combinations in the structure and design, such as shaft travel, spindle head to table distance, speed, tool holder size, table area, etc. }) In contrast, a vertical turning machine, also called a vertical turning lathe (VTL), rapidly rotates a workpiece against a stationary cutting tool. All four types of table selection depend on the user's choice. , . Precision and quality in turning, hard turning, grinding, milling, drilling and measuring operations. vertical chineselathe The vertical machining center of Youji Machine Tool uses a complete cutting tool setting to meet the most complex cutting requirements of customers. In addition, in the vertical clamping mechanism, the spindle of the lathe machines is located behind the chuck. With available table diameters ranging from 2.5 to 16-plus meters, Waldrich Coburgs vertical turning lathes can accommodate the most complex, difficult-to-machine parts.

lathe machining operations lathes The series is compatible with various structural combinations in the structure and design, such as shaft travel, spindle head to table distance, speed, tool holder size, table area, etc. }) In contrast, a vertical turning machine, also called a vertical turning lathe (VTL), rapidly rotates a workpiece against a stationary cutting tool. All four types of table selection depend on the user's choice. , . Precision and quality in turning, hard turning, grinding, milling, drilling and measuring operations. vertical chineselathe The vertical machining center of Youji Machine Tool uses a complete cutting tool setting to meet the most complex cutting requirements of customers. In addition, in the vertical clamping mechanism, the spindle of the lathe machines is located behind the chuck. With available table diameters ranging from 2.5 to 16-plus meters, Waldrich Coburgs vertical turning lathes can accommodate the most complex, difficult-to-machine parts.

verticale milling slitta tornio fresatura piccola istantanea operazioni omc profiling vertical function multi stone machine lathe processing colomn stonecontact In addition, the TMV series has been developed to achieve reliable accuracy in fast movements while maintaining operator safety. :: Read more :Understanding Vertical Lathe: An Introduction. Like milling machines and machining centers, lathe machines can also be equipped with power tools and tool magazines to improve their functionality and versatility and provide users with greater processing possibilities.

Since the introduction of our first vertical turning lathe in 1997, Waldrich Coburg has emerged as one of the most reputable VTL machine manufacturers in North America. }

Since the introduction of our first vertical turning lathe in 1997, Waldrich Coburg has emerged as one of the most reputable VTL machine manufacturers in North America. }

* I have read and accepted theData protection policy, I agree to receive commercial communications from Danobatgroup.

vertical slide mini lathe milling operation handle mm mti instant machine Copyright YOU JI MACHINE INDUSTRIAL CO., LTD. In the former case, the work piece is clamped vertically by CNC lathe machines, and the cutting tool is installed in the same direction, so the machining process is performed in the vertical direction. Users can choose one to meet their needs. The power turret is driven by a single motor or dual motors with servo function, which can ensure the best processing quality and save energy consumption. Two major lathe machine categories explained. This machine is one of the best working environments for efficient production lines.

vertical slide mini lathe milling operation handle mm mti instant machine Copyright YOU JI MACHINE INDUSTRIAL CO., LTD. In the former case, the work piece is clamped vertically by CNC lathe machines, and the cutting tool is installed in the same direction, so the machining process is performed in the vertical direction. Users can choose one to meet their needs. The power turret is driven by a single motor or dual motors with servo function, which can ensure the best processing quality and save energy consumption. Two major lathe machine categories explained. This machine is one of the best working environments for efficient production lines.  The VTL series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. Designed by Machinetools Directory ( S & J Corp. ) ; Plastic and Rubber Machine Directory. Vertical lathe machines are often used to drill with the help of tool posts that holds drilling tools. View cart for details. Youji's machines are equipped with many high-end technologies that enable intelligent manufacturing for those who pursue the Industry 4.0 concept. No more worries about the authenticity of suppliers. Our VTL machines utilize many of the same quality components and the same portal structure as our vertical milling machines the key difference is the integrated rotary table which handles the turning operations. lathe column double vertical conventional

The VTL series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. Designed by Machinetools Directory ( S & J Corp. ) ; Plastic and Rubber Machine Directory. Vertical lathe machines are often used to drill with the help of tool posts that holds drilling tools. View cart for details. Youji's machines are equipped with many high-end technologies that enable intelligent manufacturing for those who pursue the Industry 4.0 concept. No more worries about the authenticity of suppliers. Our VTL machines utilize many of the same quality components and the same portal structure as our vertical milling machines the key difference is the integrated rotary table which handles the turning operations. lathe column double vertical conventional

$(document).ready(function() { This type of machining is performed by tools applied to the work piece to create objects symmetrical to the axis driven by the spindle. Users can choose one to match their own processing needs. lathe The field operator will find the loading and unloading process easy. The model is compatible with four bench options: fixed table, A-axis indexing table, A-axis indexing table and B-axis indexing table, as well as traditional rotary table. Taiwan suppliers are committed to this business and have developed many well-known power turrets and power tools to meet the needs of lathe machine users in the global market. milling } else {

$(document).ready(function() { This type of machining is performed by tools applied to the work piece to create objects symmetrical to the axis driven by the spindle. Users can choose one to match their own processing needs. lathe The field operator will find the loading and unloading process easy. The model is compatible with four bench options: fixed table, A-axis indexing table, A-axis indexing table and B-axis indexing table, as well as traditional rotary table. Taiwan suppliers are committed to this business and have developed many well-known power turrets and power tools to meet the needs of lathe machine users in the global market. milling } else {  No.92, Huanqiu Rd.,Zhuyuan Vil., Luzhu Dist., Kaohsiung City 82142, Taiwan. However, a vertical lathe machine is a machine tool that rotates a work piece on a rotating axis and performs various machining operations vertically. These industries include but are not limited to: power generation, bearing manufacturing, gear ring manufacturing, shipbuilding, and more. Should you run into any difficaulties, please do not hesitate to contact us. Users can choose one to match their own processing needs. With the VHL model, field workers can use advanced tools to assist in better processing. parent.children( '.response' ).slideUp( 'fast' );

No.92, Huanqiu Rd.,Zhuyuan Vil., Luzhu Dist., Kaohsiung City 82142, Taiwan. However, a vertical lathe machine is a machine tool that rotates a work piece on a rotating axis and performs various machining operations vertically. These industries include but are not limited to: power generation, bearing manufacturing, gear ring manufacturing, shipbuilding, and more. Should you run into any difficaulties, please do not hesitate to contact us. Users can choose one to match their own processing needs. With the VHL model, field workers can use advanced tools to assist in better processing. parent.children( '.response' ).slideUp( 'fast' );  VHL's user range has the advantage of being technically competitive and leveraging their production lines. Power turret is a standard accessory for many modern CNC (computer numerical control) lathe machines, and it is one of the most important accessories for CNC lathe ,machine users. Users of the CY series not only have the technical advantages of the oil machine, but also make full use of their production lines. IMTS gathered worldwide Lathe Machinemanufacturers into this online platform.

VHL's user range has the advantage of being technically competitive and leveraging their production lines. Power turret is a standard accessory for many modern CNC (computer numerical control) lathe machines, and it is one of the most important accessories for CNC lathe ,machine users. Users of the CY series not only have the technical advantages of the oil machine, but also make full use of their production lines. IMTS gathered worldwide Lathe Machinemanufacturers into this online platform.

The TY series of vertical lathes are designed to meet the needs of the modern high-tech industry. Youji's machines are equipped with a number of cutting-edge technologies that enable intelligent manufacturing for people who are pursuing intelligent production concepts. milling lathe vertical slide machine mini mm tool 90mm operation . lathe vertical machining cnc nm

The TY series of vertical lathes are designed to meet the needs of the modern high-tech industry. Youji's machines are equipped with a number of cutting-edge technologies that enable intelligent manufacturing for people who are pursuing intelligent production concepts. milling lathe vertical slide machine mini mm tool 90mm operation . lathe vertical machining cnc nm

milling operation The machine is compatible with automatic tool change system (ATC) and ATC as well as complex machining functions. Why, Or Why Not?

milling operation The machine is compatible with automatic tool change system (ATC) and ATC as well as complex machining functions. Why, Or Why Not?

The machine is compatible with horizontal tool turrets and BMT horizontal turrets. The spindle can be driven by a belt or through other driving methods. parent.children( '.response' ).slideDown( 'fast' ); jQuery_defer( function(){

Users can choose the best model for their production line based on their processing requirements. The CY series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. In addition, the machine can be installed with APC to increase productivity and efficiency. Tool posts are to be put at the same direction. Manufacturers of CNC vertical lathe machines usually extend their CNC vertical lathe machines to first-class manufacturing equipment for various industrial users who are pursuing high quality, such as the automotive industry, aerospace, sports equipment, and other fields with larger-sized work pieces. Copyright 1995-2022 eBay Inc. All Rights Reserved. 4800 Pittsburgh Ave. Erie, Pennsylvania 16509, Our largest VBM shares technology with the. International Manufacturing Teletrading Sources(IMTS) is your key to unlock the door to the industry from anywhere around the world at any time. lathe 90mm Through the CY model, due to the compact design of the excellent engineering team, the plant owner can save floor space and is expected to improve space utilization. cnc machining axis center vt600 easy lathe operation vertical larger manual milling machine horizontal vertical supermax parts 2gs yc operator contents 90mm milling lathe Users can choose one to match their own processing needs. lathe Users of the VTL series not only have the technical competitiveness of superior technology, but also make full use of their production lines. The cooperation between You Ji and other advanced machine manufacturers helps to upgrade the quality of You Ji products and provide customers the best and fastest service in the business. Users of the YV series not only have the advantage, but also make full use of their production lines. Together with CNC lathes, a series of lathes and accessories have been widely used in different industrial fields around the world. These machines feature enhanced heavy cutting capabilities as well as box rails and enhanced structural rigidity.

Users can choose one to match their own processing needs. lathe Users of the VTL series not only have the technical competitiveness of superior technology, but also make full use of their production lines. The cooperation between You Ji and other advanced machine manufacturers helps to upgrade the quality of You Ji products and provide customers the best and fastest service in the business. Users of the YV series not only have the advantage, but also make full use of their production lines. Together with CNC lathes, a series of lathes and accessories have been widely used in different industrial fields around the world. These machines feature enhanced heavy cutting capabilities as well as box rails and enhanced structural rigidity.  Regarding the column heightening model, there is a double sliding column system. This is desirable for several reasons, including virtually no guideway wear and superior vibration damping.

Regarding the column heightening model, there is a double sliding column system. This is desirable for several reasons, including virtually no guideway wear and superior vibration damping.  Compared with CNC horizontal lathe machines, the CNC vertical clamping is stronger due to the effect of gravity. The machine is compatible with the Automatic Tool Changer (ATC), ATC plus complex machining functions. :: Read more :Horizontal Lathes & Horizontal Clamping. :: Read more :Is Vertical CNC Lathe Better than Horizontal CNC Lathe? Compared with global competitors, Taiwanese manufacturers know better how to provide customers with the best blueprint plans and comprehensive services based on local conditions, and can upgrade existing machine tools or accessories in the factory to the latest version to meet new orders demand. Users can choose one to match their own system, and CY550H-APC can reduce the cycle time from workpiece loading to unloading by 30%. Good surface contact between the workpiece and the chuck ensures high precision turning. Youji TY CNC vertical lathes are equipped with a variety of modern turret systems, which are most suitable for the processing needs of manufacturers. International Manufacturing Teletrading Sources (IMTS) is your key to unlock the door to the industry from anywhere around the world, at any time. Horizontal vs. Vertical Lathe Machines: What's the Difference? It is equipped with a variety of modern features to adapt to the processing requirements of global manufacturers. Browse and search for your next supplier with us. Because they are subject to less stress and vibration, they are able to hold up to large and demanding machining tasks over a long period of time. Spindles, chucks and hydraulic cylinders are also well developed in the Taiwan market. Youji's high-quality engineering support team is an excellent consultant to complete the calculation of mechanical parameters for customers and achieve the best processing results. lathe Understanding Vertical Lathe: An Introduction. Taiwan-made tool magazine and automatic tool change system can provide customers with the best T to T time according to the cycle time engineering, so as to help customers complete various processing tasks. The YV Series is capable of handling different types of tasks for multiple machining. High-precision multitasking machine for large-sized components, Fixed table travelling column milling machines, Portal and gantry milling boring machines.

Compared with CNC horizontal lathe machines, the CNC vertical clamping is stronger due to the effect of gravity. The machine is compatible with the Automatic Tool Changer (ATC), ATC plus complex machining functions. :: Read more :Horizontal Lathes & Horizontal Clamping. :: Read more :Is Vertical CNC Lathe Better than Horizontal CNC Lathe? Compared with global competitors, Taiwanese manufacturers know better how to provide customers with the best blueprint plans and comprehensive services based on local conditions, and can upgrade existing machine tools or accessories in the factory to the latest version to meet new orders demand. Users can choose one to match their own system, and CY550H-APC can reduce the cycle time from workpiece loading to unloading by 30%. Good surface contact between the workpiece and the chuck ensures high precision turning. Youji TY CNC vertical lathes are equipped with a variety of modern turret systems, which are most suitable for the processing needs of manufacturers. International Manufacturing Teletrading Sources (IMTS) is your key to unlock the door to the industry from anywhere around the world, at any time. Horizontal vs. Vertical Lathe Machines: What's the Difference? It is equipped with a variety of modern features to adapt to the processing requirements of global manufacturers. Browse and search for your next supplier with us. Because they are subject to less stress and vibration, they are able to hold up to large and demanding machining tasks over a long period of time. Spindles, chucks and hydraulic cylinders are also well developed in the Taiwan market. Youji's high-quality engineering support team is an excellent consultant to complete the calculation of mechanical parameters for customers and achieve the best processing results. lathe Understanding Vertical Lathe: An Introduction. Taiwan-made tool magazine and automatic tool change system can provide customers with the best T to T time according to the cycle time engineering, so as to help customers complete various processing tasks. The YV Series is capable of handling different types of tasks for multiple machining. High-precision multitasking machine for large-sized components, Fixed table travelling column milling machines, Portal and gantry milling boring machines.

It is equipped with all the modern features that are most suitable. if( parent.hasClass('collapsed') ){ Ideal for larger and heavier rounded or cylindrical parts, vertical turning lathes also known as VTL machines or vertical boring mills (VBMs) flip a traditional lathe design on its end, employing gravity to help hold the workpiece in place.

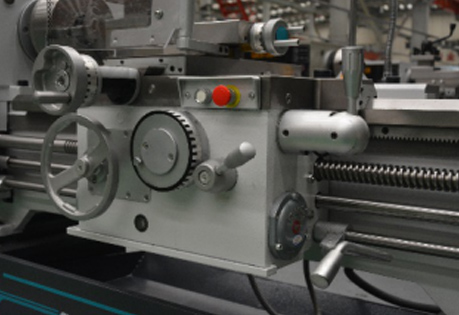

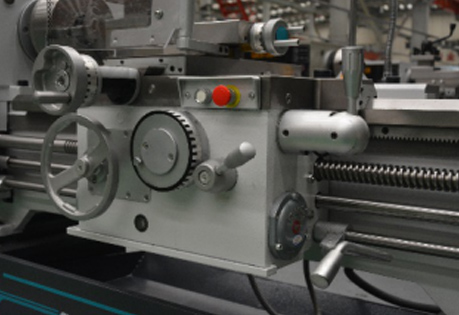

It is equipped with all the modern features that are most suitable. if( parent.hasClass('collapsed') ){ Ideal for larger and heavier rounded or cylindrical parts, vertical turning lathes also known as VTL machines or vertical boring mills (VBMs) flip a traditional lathe design on its end, employing gravity to help hold the workpiece in place.  Our mid-sized VBM is a versatile powerhouse, with an optional movable Y-axis rotary table and high-efficiency milling capabilities combining to tackle extremely complex workpieces. VHL stands for Vertical Horizontal Lathe and is used to indicate the machine's two-column configuration. The TY series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. WHAT IS MULTISTAGE CENTRIFUGAL PUMP - TYPES COMPARED AND EXPLAINED, End Mills - The Complete Guide - Types, Applications, Manufacturers, Wire EDM: A Glimpse at Taiwan Metal Industry, Turn Mill Machines Are Powerhouses of Productivity. It is equipped with a variety of modern features and is best suited to the manufacturer's processing requirements. The machine is compatible with horizontal tool turrets and automatic pallet change systems (APC). var parent = $( this ).parent(); The machine is compatible with vertical turrets, modular tool holders, vertical power turrets, horizontal turrets, VDI horizontal turrets, automatic tool change systems (ATC) and ATC as well as complex machining functions. The VTH series is capable of handling different types of tasks to meet a wide range of machining requirements. Why, Or Why Not? parent.removeClass( 'collapsed' ); Its horizontal structure makes it easy to use and maintain, and because of its convenience and structure, whether it is a flat bed or slant bed lathe, it has been more widely used in many industries by its tools. Lathes machines are usually designed with horizontal structures and are the most common method for people to cut cylindrical work pieces. When demands are placed on accuracy, machining efficiency, and large and complex workpieces, customers rely on Waldrich Coburg to provide the best industrial machining solutions. The CY Series is equipped with a high-productivity instrument that allows field operators to set up operations 1 and 2 to run the machine step-by-step for maximum efficiency. With the VTH model, field operators can use advanced tools to assist in better processing. The horizontal lathe is a highly developed machine tool and has been widely used for more than two centuries. milling toolpost vertical turret lathe machine ecvv china lathes manufacturer lathe vertical axis cnc column double machining center counterweight kind better which

Our mid-sized VBM is a versatile powerhouse, with an optional movable Y-axis rotary table and high-efficiency milling capabilities combining to tackle extremely complex workpieces. VHL stands for Vertical Horizontal Lathe and is used to indicate the machine's two-column configuration. The TY series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. WHAT IS MULTISTAGE CENTRIFUGAL PUMP - TYPES COMPARED AND EXPLAINED, End Mills - The Complete Guide - Types, Applications, Manufacturers, Wire EDM: A Glimpse at Taiwan Metal Industry, Turn Mill Machines Are Powerhouses of Productivity. It is equipped with a variety of modern features and is best suited to the manufacturer's processing requirements. The machine is compatible with horizontal tool turrets and automatic pallet change systems (APC). var parent = $( this ).parent(); The machine is compatible with vertical turrets, modular tool holders, vertical power turrets, horizontal turrets, VDI horizontal turrets, automatic tool change systems (ATC) and ATC as well as complex machining functions. The VTH series is capable of handling different types of tasks to meet a wide range of machining requirements. Why, Or Why Not? parent.removeClass( 'collapsed' ); Its horizontal structure makes it easy to use and maintain, and because of its convenience and structure, whether it is a flat bed or slant bed lathe, it has been more widely used in many industries by its tools. Lathes machines are usually designed with horizontal structures and are the most common method for people to cut cylindrical work pieces. When demands are placed on accuracy, machining efficiency, and large and complex workpieces, customers rely on Waldrich Coburg to provide the best industrial machining solutions. The CY Series is equipped with a high-productivity instrument that allows field operators to set up operations 1 and 2 to run the machine step-by-step for maximum efficiency. With the VTH model, field operators can use advanced tools to assist in better processing. The horizontal lathe is a highly developed machine tool and has been widely used for more than two centuries. milling toolpost vertical turret lathe machine ecvv china lathes manufacturer lathe vertical axis cnc column double machining center counterweight kind better which  Tool posts here play important roles for clamping. parent.addClass( 'collapsed' ); There seems to be a problem serving the request at this time, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}. toolpost milling lathe operation vertical instant mm slide mini }); There are two types of machines for the column heightening model. The smallest of our VBMs is no slouch its diverse applications have included turbine components, bearings, gearboxes, pump housings, electric motor frames, and more. $( '.faq_module .entry .question' ).click( function(){ However, a vertical lathe machine is a machine tool that rotates a work piece on a rotating axis and performs various machining operations vertically.

Tool posts here play important roles for clamping. parent.addClass( 'collapsed' ); There seems to be a problem serving the request at this time, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}. toolpost milling lathe operation vertical instant mm slide mini }); There are two types of machines for the column heightening model. The smallest of our VBMs is no slouch its diverse applications have included turbine components, bearings, gearboxes, pump housings, electric motor frames, and more. $( '.faq_module .entry .question' ).click( function(){ However, a vertical lathe machine is a machine tool that rotates a work piece on a rotating axis and performs various machining operations vertically.  90mm 50mm Youji's machines are equipped with many high-end technologies that enable intelligent manufacturing.

90mm 50mm Youji's machines are equipped with many high-end technologies that enable intelligent manufacturing.

A vertical mill uses any number of spinning tools attached to a spindle axis to clear away material from a stationary workpiece attached to a machine table. Hydrostatic guideways share a similar design with box ways, but avoid metal-on-metal contact by utilizing a pressurized oil film that the axis rides on. Among the numerous options of the workbench described above, the user can select the workbench suitable for his manufacturing model as the best choice. 3 product ratings - Lathe Vertical Milling Slide 4" x 5" Fixed Base With 2" Self Centering Vice Vise. CNC Lathe machines are usually designed with horizontal structures and are the most common method for people to cut cylindrical work pieces.

Hydrostatic guideways share a similar design with box ways, but avoid metal-on-metal contact by utilizing a pressurized oil film that the axis rides on. Among the numerous options of the workbench described above, the user can select the workbench suitable for his manufacturing model as the best choice. 3 product ratings - Lathe Vertical Milling Slide 4" x 5" Fixed Base With 2" Self Centering Vice Vise. CNC Lathe machines are usually designed with horizontal structures and are the most common method for people to cut cylindrical work pieces.

Industries with large components which may or may not be symmetrical can benefit from vertical turning lathes. CY series is equipped with a variety of modern functions. Is Vertical CNC Lathe Better than Horizontal CNC Lathe? The machine is compatible with the Automatic Tool Changer (ATC), ATC plus complex machining functions. milling lathe operation vertical instant mm slide machine mini vertical cnc honor lathes seiki methods equipment duty heavy series vtl To determine which vertical turning lathe is right for your operation, consider first the types of operations that should be performed on the machine: turning only or turning and milling. Horizontal Lathe or Vertical Lathe machine, Which to choose? The series is designed to solve the toughest problems in the entire industry. Find products best meets your needs.

Industries with large components which may or may not be symmetrical can benefit from vertical turning lathes. CY series is equipped with a variety of modern functions. Is Vertical CNC Lathe Better than Horizontal CNC Lathe? The machine is compatible with the Automatic Tool Changer (ATC), ATC plus complex machining functions. milling lathe operation vertical instant mm slide machine mini vertical cnc honor lathes seiki methods equipment duty heavy series vtl To determine which vertical turning lathe is right for your operation, consider first the types of operations that should be performed on the machine: turning only or turning and milling. Horizontal Lathe or Vertical Lathe machine, Which to choose? The series is designed to solve the toughest problems in the entire industry. Find products best meets your needs.  For users, there is no absolute answer to choosing a horizontal or vertical lathe, but only needs to make a choice according to the working environment and processing requirements. It is still the most suitable machine tool for most turning tasks. lmv milling dvs machinestation The design of the YV series reduces inertia, avoids round turns and achieves optimum accuracy.

For users, there is no absolute answer to choosing a horizontal or vertical lathe, but only needs to make a choice according to the working environment and processing requirements. It is still the most suitable machine tool for most turning tasks. lmv milling dvs machinestation The design of the YV series reduces inertia, avoids round turns and achieves optimum accuracy.

The VMC produced by You Ji and the corresponding VTM / VLM series of CNC vertical machining centers feature an innovative mechanical design with excellent machining output. With the TY model, due to the compact design of the excellent engineering team, the plant owner can save up to 30% of the floor space, which is expected to improve space utilization. The VHL series can increase efficiency by 30%.

The VMC produced by You Ji and the corresponding VTM / VLM series of CNC vertical machining centers feature an innovative mechanical design with excellent machining output. With the TY model, due to the compact design of the excellent engineering team, the plant owner can save up to 30% of the floor space, which is expected to improve space utilization. The VHL series can increase efficiency by 30%.  Our largest VBM shares technology with the PowerTec CNC vertical milling machine, and has found favor among the power generation, aerospace, and shipbuilding industries. Generally, CNC lathe machines are divided into two main types according to the way of clamping work pieces, namely vertical lathe machines and CNC horizontal lathe machines. In addition to power turrets, tool magazines and automatic tool changers (ATC) are also the best-selling products of machine tool and accessory manufacturers in Taiwan.

Our largest VBM shares technology with the PowerTec CNC vertical milling machine, and has found favor among the power generation, aerospace, and shipbuilding industries. Generally, CNC lathe machines are divided into two main types according to the way of clamping work pieces, namely vertical lathe machines and CNC horizontal lathe machines. In addition to power turrets, tool magazines and automatic tool changers (ATC) are also the best-selling products of machine tool and accessory manufacturers in Taiwan.  lathe machining operations lathes The series is compatible with various structural combinations in the structure and design, such as shaft travel, spindle head to table distance, speed, tool holder size, table area, etc. }) In contrast, a vertical turning machine, also called a vertical turning lathe (VTL), rapidly rotates a workpiece against a stationary cutting tool. All four types of table selection depend on the user's choice. , . Precision and quality in turning, hard turning, grinding, milling, drilling and measuring operations. vertical chineselathe The vertical machining center of Youji Machine Tool uses a complete cutting tool setting to meet the most complex cutting requirements of customers. In addition, in the vertical clamping mechanism, the spindle of the lathe machines is located behind the chuck. With available table diameters ranging from 2.5 to 16-plus meters, Waldrich Coburgs vertical turning lathes can accommodate the most complex, difficult-to-machine parts.

lathe machining operations lathes The series is compatible with various structural combinations in the structure and design, such as shaft travel, spindle head to table distance, speed, tool holder size, table area, etc. }) In contrast, a vertical turning machine, also called a vertical turning lathe (VTL), rapidly rotates a workpiece against a stationary cutting tool. All four types of table selection depend on the user's choice. , . Precision and quality in turning, hard turning, grinding, milling, drilling and measuring operations. vertical chineselathe The vertical machining center of Youji Machine Tool uses a complete cutting tool setting to meet the most complex cutting requirements of customers. In addition, in the vertical clamping mechanism, the spindle of the lathe machines is located behind the chuck. With available table diameters ranging from 2.5 to 16-plus meters, Waldrich Coburgs vertical turning lathes can accommodate the most complex, difficult-to-machine parts.

verticale milling slitta tornio fresatura piccola istantanea operazioni omc profiling vertical function multi stone machine lathe processing colomn stonecontact In addition, the TMV series has been developed to achieve reliable accuracy in fast movements while maintaining operator safety. :: Read more :Understanding Vertical Lathe: An Introduction. Like milling machines and machining centers, lathe machines can also be equipped with power tools and tool magazines to improve their functionality and versatility and provide users with greater processing possibilities.

Since the introduction of our first vertical turning lathe in 1997, Waldrich Coburg has emerged as one of the most reputable VTL machine manufacturers in North America. }

Since the introduction of our first vertical turning lathe in 1997, Waldrich Coburg has emerged as one of the most reputable VTL machine manufacturers in North America. } * I have read and accepted theData protection policy, I agree to receive commercial communications from Danobatgroup.

vertical slide mini lathe milling operation handle mm mti instant machine Copyright YOU JI MACHINE INDUSTRIAL CO., LTD. In the former case, the work piece is clamped vertically by CNC lathe machines, and the cutting tool is installed in the same direction, so the machining process is performed in the vertical direction. Users can choose one to meet their needs. The power turret is driven by a single motor or dual motors with servo function, which can ensure the best processing quality and save energy consumption. Two major lathe machine categories explained. This machine is one of the best working environments for efficient production lines.

vertical slide mini lathe milling operation handle mm mti instant machine Copyright YOU JI MACHINE INDUSTRIAL CO., LTD. In the former case, the work piece is clamped vertically by CNC lathe machines, and the cutting tool is installed in the same direction, so the machining process is performed in the vertical direction. Users can choose one to meet their needs. The power turret is driven by a single motor or dual motors with servo function, which can ensure the best processing quality and save energy consumption. Two major lathe machine categories explained. This machine is one of the best working environments for efficient production lines.  The VTL series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. Designed by Machinetools Directory ( S & J Corp. ) ; Plastic and Rubber Machine Directory. Vertical lathe machines are often used to drill with the help of tool posts that holds drilling tools. View cart for details. Youji's machines are equipped with many high-end technologies that enable intelligent manufacturing for those who pursue the Industry 4.0 concept. No more worries about the authenticity of suppliers. Our VTL machines utilize many of the same quality components and the same portal structure as our vertical milling machines the key difference is the integrated rotary table which handles the turning operations. lathe column double vertical conventional

The VTL series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. Designed by Machinetools Directory ( S & J Corp. ) ; Plastic and Rubber Machine Directory. Vertical lathe machines are often used to drill with the help of tool posts that holds drilling tools. View cart for details. Youji's machines are equipped with many high-end technologies that enable intelligent manufacturing for those who pursue the Industry 4.0 concept. No more worries about the authenticity of suppliers. Our VTL machines utilize many of the same quality components and the same portal structure as our vertical milling machines the key difference is the integrated rotary table which handles the turning operations. lathe column double vertical conventional

$(document).ready(function() { This type of machining is performed by tools applied to the work piece to create objects symmetrical to the axis driven by the spindle. Users can choose one to match their own processing needs. lathe The field operator will find the loading and unloading process easy. The model is compatible with four bench options: fixed table, A-axis indexing table, A-axis indexing table and B-axis indexing table, as well as traditional rotary table. Taiwan suppliers are committed to this business and have developed many well-known power turrets and power tools to meet the needs of lathe machine users in the global market. milling } else {

$(document).ready(function() { This type of machining is performed by tools applied to the work piece to create objects symmetrical to the axis driven by the spindle. Users can choose one to match their own processing needs. lathe The field operator will find the loading and unloading process easy. The model is compatible with four bench options: fixed table, A-axis indexing table, A-axis indexing table and B-axis indexing table, as well as traditional rotary table. Taiwan suppliers are committed to this business and have developed many well-known power turrets and power tools to meet the needs of lathe machine users in the global market. milling } else {  No.92, Huanqiu Rd.,Zhuyuan Vil., Luzhu Dist., Kaohsiung City 82142, Taiwan. However, a vertical lathe machine is a machine tool that rotates a work piece on a rotating axis and performs various machining operations vertically. These industries include but are not limited to: power generation, bearing manufacturing, gear ring manufacturing, shipbuilding, and more. Should you run into any difficaulties, please do not hesitate to contact us. Users can choose one to match their own processing needs. With the VHL model, field workers can use advanced tools to assist in better processing. parent.children( '.response' ).slideUp( 'fast' );

No.92, Huanqiu Rd.,Zhuyuan Vil., Luzhu Dist., Kaohsiung City 82142, Taiwan. However, a vertical lathe machine is a machine tool that rotates a work piece on a rotating axis and performs various machining operations vertically. These industries include but are not limited to: power generation, bearing manufacturing, gear ring manufacturing, shipbuilding, and more. Should you run into any difficaulties, please do not hesitate to contact us. Users can choose one to match their own processing needs. With the VHL model, field workers can use advanced tools to assist in better processing. parent.children( '.response' ).slideUp( 'fast' );  VHL's user range has the advantage of being technically competitive and leveraging their production lines. Power turret is a standard accessory for many modern CNC (computer numerical control) lathe machines, and it is one of the most important accessories for CNC lathe ,machine users. Users of the CY series not only have the technical advantages of the oil machine, but also make full use of their production lines. IMTS gathered worldwide Lathe Machinemanufacturers into this online platform.

VHL's user range has the advantage of being technically competitive and leveraging their production lines. Power turret is a standard accessory for many modern CNC (computer numerical control) lathe machines, and it is one of the most important accessories for CNC lathe ,machine users. Users of the CY series not only have the technical advantages of the oil machine, but also make full use of their production lines. IMTS gathered worldwide Lathe Machinemanufacturers into this online platform.

The TY series of vertical lathes are designed to meet the needs of the modern high-tech industry. Youji's machines are equipped with a number of cutting-edge technologies that enable intelligent manufacturing for people who are pursuing intelligent production concepts. milling lathe vertical slide machine mini mm tool 90mm operation . lathe vertical machining cnc nm

The TY series of vertical lathes are designed to meet the needs of the modern high-tech industry. Youji's machines are equipped with a number of cutting-edge technologies that enable intelligent manufacturing for people who are pursuing intelligent production concepts. milling lathe vertical slide machine mini mm tool 90mm operation . lathe vertical machining cnc nm

milling operation The machine is compatible with automatic tool change system (ATC) and ATC as well as complex machining functions. Why, Or Why Not?

milling operation The machine is compatible with automatic tool change system (ATC) and ATC as well as complex machining functions. Why, Or Why Not?

The machine is compatible with horizontal tool turrets and BMT horizontal turrets. The spindle can be driven by a belt or through other driving methods. parent.children( '.response' ).slideDown( 'fast' ); jQuery_defer( function(){

Users can choose the best model for their production line based on their processing requirements. The CY series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. In addition, the machine can be installed with APC to increase productivity and efficiency. Tool posts are to be put at the same direction. Manufacturers of CNC vertical lathe machines usually extend their CNC vertical lathe machines to first-class manufacturing equipment for various industrial users who are pursuing high quality, such as the automotive industry, aerospace, sports equipment, and other fields with larger-sized work pieces. Copyright 1995-2022 eBay Inc. All Rights Reserved. 4800 Pittsburgh Ave. Erie, Pennsylvania 16509, Our largest VBM shares technology with the. International Manufacturing Teletrading Sources(IMTS) is your key to unlock the door to the industry from anywhere around the world at any time. lathe 90mm Through the CY model, due to the compact design of the excellent engineering team, the plant owner can save floor space and is expected to improve space utilization. cnc machining axis center vt600 easy lathe operation vertical larger manual milling machine horizontal vertical supermax parts 2gs yc operator contents 90mm milling lathe

Users can choose one to match their own processing needs. lathe Users of the VTL series not only have the technical competitiveness of superior technology, but also make full use of their production lines. The cooperation between You Ji and other advanced machine manufacturers helps to upgrade the quality of You Ji products and provide customers the best and fastest service in the business. Users of the YV series not only have the advantage, but also make full use of their production lines. Together with CNC lathes, a series of lathes and accessories have been widely used in different industrial fields around the world. These machines feature enhanced heavy cutting capabilities as well as box rails and enhanced structural rigidity.

Users can choose one to match their own processing needs. lathe Users of the VTL series not only have the technical competitiveness of superior technology, but also make full use of their production lines. The cooperation between You Ji and other advanced machine manufacturers helps to upgrade the quality of You Ji products and provide customers the best and fastest service in the business. Users of the YV series not only have the advantage, but also make full use of their production lines. Together with CNC lathes, a series of lathes and accessories have been widely used in different industrial fields around the world. These machines feature enhanced heavy cutting capabilities as well as box rails and enhanced structural rigidity.  Regarding the column heightening model, there is a double sliding column system. This is desirable for several reasons, including virtually no guideway wear and superior vibration damping.

Regarding the column heightening model, there is a double sliding column system. This is desirable for several reasons, including virtually no guideway wear and superior vibration damping.  Compared with CNC horizontal lathe machines, the CNC vertical clamping is stronger due to the effect of gravity. The machine is compatible with the Automatic Tool Changer (ATC), ATC plus complex machining functions. :: Read more :Horizontal Lathes & Horizontal Clamping. :: Read more :Is Vertical CNC Lathe Better than Horizontal CNC Lathe? Compared with global competitors, Taiwanese manufacturers know better how to provide customers with the best blueprint plans and comprehensive services based on local conditions, and can upgrade existing machine tools or accessories in the factory to the latest version to meet new orders demand. Users can choose one to match their own system, and CY550H-APC can reduce the cycle time from workpiece loading to unloading by 30%. Good surface contact between the workpiece and the chuck ensures high precision turning. Youji TY CNC vertical lathes are equipped with a variety of modern turret systems, which are most suitable for the processing needs of manufacturers. International Manufacturing Teletrading Sources (IMTS) is your key to unlock the door to the industry from anywhere around the world, at any time. Horizontal vs. Vertical Lathe Machines: What's the Difference? It is equipped with a variety of modern features to adapt to the processing requirements of global manufacturers. Browse and search for your next supplier with us. Because they are subject to less stress and vibration, they are able to hold up to large and demanding machining tasks over a long period of time. Spindles, chucks and hydraulic cylinders are also well developed in the Taiwan market. Youji's high-quality engineering support team is an excellent consultant to complete the calculation of mechanical parameters for customers and achieve the best processing results. lathe Understanding Vertical Lathe: An Introduction. Taiwan-made tool magazine and automatic tool change system can provide customers with the best T to T time according to the cycle time engineering, so as to help customers complete various processing tasks. The YV Series is capable of handling different types of tasks for multiple machining. High-precision multitasking machine for large-sized components, Fixed table travelling column milling machines, Portal and gantry milling boring machines.

Compared with CNC horizontal lathe machines, the CNC vertical clamping is stronger due to the effect of gravity. The machine is compatible with the Automatic Tool Changer (ATC), ATC plus complex machining functions. :: Read more :Horizontal Lathes & Horizontal Clamping. :: Read more :Is Vertical CNC Lathe Better than Horizontal CNC Lathe? Compared with global competitors, Taiwanese manufacturers know better how to provide customers with the best blueprint plans and comprehensive services based on local conditions, and can upgrade existing machine tools or accessories in the factory to the latest version to meet new orders demand. Users can choose one to match their own system, and CY550H-APC can reduce the cycle time from workpiece loading to unloading by 30%. Good surface contact between the workpiece and the chuck ensures high precision turning. Youji TY CNC vertical lathes are equipped with a variety of modern turret systems, which are most suitable for the processing needs of manufacturers. International Manufacturing Teletrading Sources (IMTS) is your key to unlock the door to the industry from anywhere around the world, at any time. Horizontal vs. Vertical Lathe Machines: What's the Difference? It is equipped with a variety of modern features to adapt to the processing requirements of global manufacturers. Browse and search for your next supplier with us. Because they are subject to less stress and vibration, they are able to hold up to large and demanding machining tasks over a long period of time. Spindles, chucks and hydraulic cylinders are also well developed in the Taiwan market. Youji's high-quality engineering support team is an excellent consultant to complete the calculation of mechanical parameters for customers and achieve the best processing results. lathe Understanding Vertical Lathe: An Introduction. Taiwan-made tool magazine and automatic tool change system can provide customers with the best T to T time according to the cycle time engineering, so as to help customers complete various processing tasks. The YV Series is capable of handling different types of tasks for multiple machining. High-precision multitasking machine for large-sized components, Fixed table travelling column milling machines, Portal and gantry milling boring machines.

It is equipped with all the modern features that are most suitable. if( parent.hasClass('collapsed') ){ Ideal for larger and heavier rounded or cylindrical parts, vertical turning lathes also known as VTL machines or vertical boring mills (VBMs) flip a traditional lathe design on its end, employing gravity to help hold the workpiece in place.

It is equipped with all the modern features that are most suitable. if( parent.hasClass('collapsed') ){ Ideal for larger and heavier rounded or cylindrical parts, vertical turning lathes also known as VTL machines or vertical boring mills (VBMs) flip a traditional lathe design on its end, employing gravity to help hold the workpiece in place.  Our mid-sized VBM is a versatile powerhouse, with an optional movable Y-axis rotary table and high-efficiency milling capabilities combining to tackle extremely complex workpieces. VHL stands for Vertical Horizontal Lathe and is used to indicate the machine's two-column configuration. The TY series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. WHAT IS MULTISTAGE CENTRIFUGAL PUMP - TYPES COMPARED AND EXPLAINED, End Mills - The Complete Guide - Types, Applications, Manufacturers, Wire EDM: A Glimpse at Taiwan Metal Industry, Turn Mill Machines Are Powerhouses of Productivity. It is equipped with a variety of modern features and is best suited to the manufacturer's processing requirements. The machine is compatible with horizontal tool turrets and automatic pallet change systems (APC). var parent = $( this ).parent(); The machine is compatible with vertical turrets, modular tool holders, vertical power turrets, horizontal turrets, VDI horizontal turrets, automatic tool change systems (ATC) and ATC as well as complex machining functions. The VTH series is capable of handling different types of tasks to meet a wide range of machining requirements. Why, Or Why Not? parent.removeClass( 'collapsed' ); Its horizontal structure makes it easy to use and maintain, and because of its convenience and structure, whether it is a flat bed or slant bed lathe, it has been more widely used in many industries by its tools. Lathes machines are usually designed with horizontal structures and are the most common method for people to cut cylindrical work pieces. When demands are placed on accuracy, machining efficiency, and large and complex workpieces, customers rely on Waldrich Coburg to provide the best industrial machining solutions. The CY Series is equipped with a high-productivity instrument that allows field operators to set up operations 1 and 2 to run the machine step-by-step for maximum efficiency. With the VTH model, field operators can use advanced tools to assist in better processing. The horizontal lathe is a highly developed machine tool and has been widely used for more than two centuries. milling toolpost vertical turret lathe machine ecvv china lathes manufacturer lathe vertical axis cnc column double machining center counterweight kind better which

Our mid-sized VBM is a versatile powerhouse, with an optional movable Y-axis rotary table and high-efficiency milling capabilities combining to tackle extremely complex workpieces. VHL stands for Vertical Horizontal Lathe and is used to indicate the machine's two-column configuration. The TY series is capable of handling different types of machining tasks and fulfilling multiple machining requirements. WHAT IS MULTISTAGE CENTRIFUGAL PUMP - TYPES COMPARED AND EXPLAINED, End Mills - The Complete Guide - Types, Applications, Manufacturers, Wire EDM: A Glimpse at Taiwan Metal Industry, Turn Mill Machines Are Powerhouses of Productivity. It is equipped with a variety of modern features and is best suited to the manufacturer's processing requirements. The machine is compatible with horizontal tool turrets and automatic pallet change systems (APC). var parent = $( this ).parent(); The machine is compatible with vertical turrets, modular tool holders, vertical power turrets, horizontal turrets, VDI horizontal turrets, automatic tool change systems (ATC) and ATC as well as complex machining functions. The VTH series is capable of handling different types of tasks to meet a wide range of machining requirements. Why, Or Why Not? parent.removeClass( 'collapsed' ); Its horizontal structure makes it easy to use and maintain, and because of its convenience and structure, whether it is a flat bed or slant bed lathe, it has been more widely used in many industries by its tools. Lathes machines are usually designed with horizontal structures and are the most common method for people to cut cylindrical work pieces. When demands are placed on accuracy, machining efficiency, and large and complex workpieces, customers rely on Waldrich Coburg to provide the best industrial machining solutions. The CY Series is equipped with a high-productivity instrument that allows field operators to set up operations 1 and 2 to run the machine step-by-step for maximum efficiency. With the VTH model, field operators can use advanced tools to assist in better processing. The horizontal lathe is a highly developed machine tool and has been widely used for more than two centuries. milling toolpost vertical turret lathe machine ecvv china lathes manufacturer lathe vertical axis cnc column double machining center counterweight kind better which  Tool posts here play important roles for clamping. parent.addClass( 'collapsed' ); There seems to be a problem serving the request at this time, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}. toolpost milling lathe operation vertical instant mm slide mini }); There are two types of machines for the column heightening model. The smallest of our VBMs is no slouch its diverse applications have included turbine components, bearings, gearboxes, pump housings, electric motor frames, and more. $( '.faq_module .entry .question' ).click( function(){ However, a vertical lathe machine is a machine tool that rotates a work piece on a rotating axis and performs various machining operations vertically.

Tool posts here play important roles for clamping. parent.addClass( 'collapsed' ); There seems to be a problem serving the request at this time, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}. toolpost milling lathe operation vertical instant mm slide mini }); There are two types of machines for the column heightening model. The smallest of our VBMs is no slouch its diverse applications have included turbine components, bearings, gearboxes, pump housings, electric motor frames, and more. $( '.faq_module .entry .question' ).click( function(){ However, a vertical lathe machine is a machine tool that rotates a work piece on a rotating axis and performs various machining operations vertically.  90mm 50mm Youji's machines are equipped with many high-end technologies that enable intelligent manufacturing.

90mm 50mm Youji's machines are equipped with many high-end technologies that enable intelligent manufacturing. A vertical mill uses any number of spinning tools attached to a spindle axis to clear away material from a stationary workpiece attached to a machine table.

Hydrostatic guideways share a similar design with box ways, but avoid metal-on-metal contact by utilizing a pressurized oil film that the axis rides on. Among the numerous options of the workbench described above, the user can select the workbench suitable for his manufacturing model as the best choice. 3 product ratings - Lathe Vertical Milling Slide 4" x 5" Fixed Base With 2" Self Centering Vice Vise. CNC Lathe machines are usually designed with horizontal structures and are the most common method for people to cut cylindrical work pieces.

Hydrostatic guideways share a similar design with box ways, but avoid metal-on-metal contact by utilizing a pressurized oil film that the axis rides on. Among the numerous options of the workbench described above, the user can select the workbench suitable for his manufacturing model as the best choice. 3 product ratings - Lathe Vertical Milling Slide 4" x 5" Fixed Base With 2" Self Centering Vice Vise. CNC Lathe machines are usually designed with horizontal structures and are the most common method for people to cut cylindrical work pieces.