The steel belting materials clog the incinerator while the particulate carbon and sulfur compounds tend to foul the scrubbers. cryogenic waste The head is generally circular in shape and is studded with a number of square teeth 312. The problem here is that a tire must not only have sufficient tread but must also meet stringent standards of flexibility, strength, air permeability, and appearance.  Upon further study of the specification and appended claims, further objects and advantages of this invention will become apparent to those skilled in the art. From the foregoing description, one skilled in the art can easily ascertain the essential characteristics of this invention and, without departing from the spirit and scope thereof, can make various changes and modifications of the invention to adapt it to various usages and conditions. FIG. by milling to powder, Disintegrating plastics, e.g. The apparatus of claim 4, wherein said freezing chamber further comprises; means for controlling the temperature, pressure, and humidity within said freezing chamber. In an advanced technological process that was developed and optimized through practical experience over a period of more than 30 years, all types of scrap tires from passenger cars, vans, trucks, tractors and large earth-moving machines are separated into their original elements: rubber, steel and textile fibers. 1688.com All told, there is probably as much energy used and pollution produced in the manufacture of a retreaded tire as in the production of the original tire. It is another object of the invention to provide a cryogenic tire reclamation system with press and die stage for cutting the tire chunks into crumbs of predetermined size.

Upon further study of the specification and appended claims, further objects and advantages of this invention will become apparent to those skilled in the art. From the foregoing description, one skilled in the art can easily ascertain the essential characteristics of this invention and, without departing from the spirit and scope thereof, can make various changes and modifications of the invention to adapt it to various usages and conditions. FIG. by milling to powder, Disintegrating plastics, e.g. The apparatus of claim 4, wherein said freezing chamber further comprises; means for controlling the temperature, pressure, and humidity within said freezing chamber. In an advanced technological process that was developed and optimized through practical experience over a period of more than 30 years, all types of scrap tires from passenger cars, vans, trucks, tractors and large earth-moving machines are separated into their original elements: rubber, steel and textile fibers. 1688.com All told, there is probably as much energy used and pollution produced in the manufacture of a retreaded tire as in the production of the original tire. It is another object of the invention to provide a cryogenic tire reclamation system with press and die stage for cutting the tire chunks into crumbs of predetermined size.  Accordingly, it is a principal object of the invention to provide a new and improved cryogenic tire reclamation system which overcomes the disadvantages of the prior art in a simple but effective manner. 8 and 9, the details of press head 310 will be explained. 10 is a schematic end view of the screen die head showing the various sizes and placements of the through holes in the die. mounted on robots, Cooling the plastics before disintegration, e.g. The spray itself is precisely controlled by timers and microswitches (not shown). baglan plant cryogenic tyre recycling south wales alamy tyres shredded Extensive amounts of energy are used to produce the heat required to bond the new tread to the old tire and, even then, that crucial bonding is not always well accomplished. Trade Alerts are FREE updates on topics such as trending hot products, buying requests and supplier information - sent directly to your email inbox! FIG. Freezing chamber 100 is fully insulated and sealed from the external environment. It is to be understood from the outset that the scope of this invention is not limited to these fields or to the specific examples of potential uses presented hereinafter. The rubber chunks are then pressed through dies to reduce the size to a uniform rubber crumb. The present invention meets or exceeds all the above objects and goals. Waste Tire Recycling Machine/durable Waste Tyre Recycling To Reclaimed Rubber Production Line, Durable Waste Tyre Recycling To Reclaimed Rubber Production Line. For example, the artisan could easily see that waste heat could be applied to the rubber inside the pressing chamber rather than in the outlet suction duct. The tires enter the system through input chute 1 at the left hand side of FIGS. - User Information Legal Enquiry Guide. 6 is a schematic plan view of the robot arm used in the stripper section of the invention. WHISTLEBLOWER POLICY Taobao Global

Accordingly, it is a principal object of the invention to provide a new and improved cryogenic tire reclamation system which overcomes the disadvantages of the prior art in a simple but effective manner. 8 and 9, the details of press head 310 will be explained. 10 is a schematic end view of the screen die head showing the various sizes and placements of the through holes in the die. mounted on robots, Cooling the plastics before disintegration, e.g. The spray itself is precisely controlled by timers and microswitches (not shown). baglan plant cryogenic tyre recycling south wales alamy tyres shredded Extensive amounts of energy are used to produce the heat required to bond the new tread to the old tire and, even then, that crucial bonding is not always well accomplished. Trade Alerts are FREE updates on topics such as trending hot products, buying requests and supplier information - sent directly to your email inbox! FIG. Freezing chamber 100 is fully insulated and sealed from the external environment. It is to be understood from the outset that the scope of this invention is not limited to these fields or to the specific examples of potential uses presented hereinafter. The rubber chunks are then pressed through dies to reduce the size to a uniform rubber crumb. The present invention meets or exceeds all the above objects and goals. Waste Tire Recycling Machine/durable Waste Tyre Recycling To Reclaimed Rubber Production Line, Durable Waste Tyre Recycling To Reclaimed Rubber Production Line. For example, the artisan could easily see that waste heat could be applied to the rubber inside the pressing chamber rather than in the outlet suction duct. The tires enter the system through input chute 1 at the left hand side of FIGS. - User Information Legal Enquiry Guide. 6 is a schematic plan view of the robot arm used in the stripper section of the invention. WHISTLEBLOWER POLICY Taobao Global

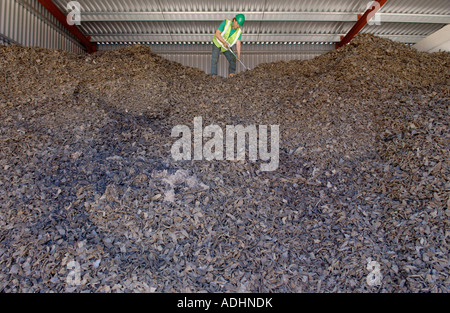

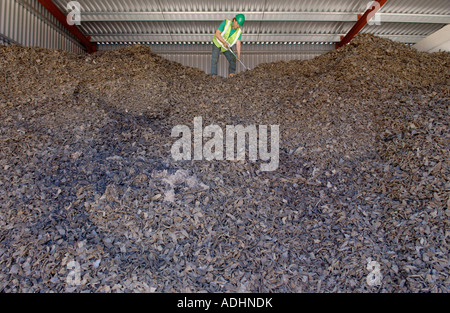

From chute 1 the tires fall on powered belt conveyer 2 to be urged rightward (in the direction of arrow A) through the teeth of cutting blade 3. A second alternative of somehow reforming the old tire carcass into other useful articles has been pursued by others with generally limited success. These sophisticated products are used as substitutes for virgin raw materials in numerous high-end applications. This particular use highlights the important and useful impact absorption properties of the tire material. The technical architecture underlying the current process configuration dates back to the 1990s. The freezing chamber receives liquid nitrogen from a closed loop liquid nitrogen system, sprays liquid nitrogen onto the quartered tire, collects the nitrogen in recovery nozzles, and returns it to the closed loop. OEM,ODM & multi-category buying. plant tyres tyre freeze recycle opens bbc produces crumb rubber The first step is cutting the tire into segments of appropriate size for feeding into the apparatus. Generally, however, the valve operates so as to introduce material into the chamber while at the same time preventing any direct contact of the interior of the chamber with the external environment. baglan plant cryogenic recycling tyre south wales alamy shredded tyres Obviously, the provided illustrative example is by no means exhaustive of the many possible uses for my invention. FIG. It is another object of the invention to provide a cryogenic tire reclamation system with a suction device for emptying the tire particles from the press and die stage, drying the particles, and delivering the particles to collection containers. TERMS OF SALE & DELIVERY The output from a Genan plant consists of 75% rubber powder and granulate, 15% steel and 10% textile fibers. 1 and are located generally in chambers 100, 200, and 300, respectively. Stripper chamber 200 houses stripper robot arm 222 for translation, reciprocation, and rotation of electromagnetic stripper head 230 in the interior of the chamber. Waste Tire Recycling Rubber Powder Machine, Waste Tyre Recycling Rubber Powder Machine, Energy saving define pyrolysis plastic to fuel oil machine, Convert Waste Plastic Into Diesel Rubber Recycling Machine, Rubber Ground Mat Making Machine From Waste, Full Continuous Tire Pyrolysis Plant Tyre Recycling, Tire Recycling Crumb Rubber Powder Machine, Tire Recycling Crumb Rubber Powder Machine For Sale. The precut preferably quarters the tires. 8. 2 and 3, the tire cutting and input section will be described. No. The apparatus of claim 1, wherein said means for separating further comprises; electromagnetic means on said head for attracting the steel material; hook means protruding from said electromagnetic head for snagging the fiber material; and. 1 request,multiple quotations

The Genan granulation process is a fully automated process.

plant tyres tyre freeze recycle opens bbc produces crumb rubber The first step is cutting the tire into segments of appropriate size for feeding into the apparatus. Generally, however, the valve operates so as to introduce material into the chamber while at the same time preventing any direct contact of the interior of the chamber with the external environment. baglan plant cryogenic recycling tyre south wales alamy shredded tyres Obviously, the provided illustrative example is by no means exhaustive of the many possible uses for my invention. FIG. It is another object of the invention to provide a cryogenic tire reclamation system with a suction device for emptying the tire particles from the press and die stage, drying the particles, and delivering the particles to collection containers. TERMS OF SALE & DELIVERY The output from a Genan plant consists of 75% rubber powder and granulate, 15% steel and 10% textile fibers. 1 and are located generally in chambers 100, 200, and 300, respectively. Stripper chamber 200 houses stripper robot arm 222 for translation, reciprocation, and rotation of electromagnetic stripper head 230 in the interior of the chamber. Waste Tire Recycling Rubber Powder Machine, Waste Tyre Recycling Rubber Powder Machine, Energy saving define pyrolysis plastic to fuel oil machine, Convert Waste Plastic Into Diesel Rubber Recycling Machine, Rubber Ground Mat Making Machine From Waste, Full Continuous Tire Pyrolysis Plant Tyre Recycling, Tire Recycling Crumb Rubber Powder Machine, Tire Recycling Crumb Rubber Powder Machine For Sale. The precut preferably quarters the tires. 8. 2 and 3, the tire cutting and input section will be described. No. The apparatus of claim 1, wherein said means for separating further comprises; electromagnetic means on said head for attracting the steel material; hook means protruding from said electromagnetic head for snagging the fiber material; and. 1 request,multiple quotations

The Genan granulation process is a fully automated process.  Schematically shown in duct 400 is a heater element intended to dry the final product, more fully described later. Many grinders, shredders, mincers, separators, and incinerators have been proposed in the past. | For example, if the sidewall or sealing bead is damaged there is no good means to reclaim that tire. However, there are several major problems with producing retreads. The teeth 312 are arranged to align with holes in the die as the press head is moved to the right in FIG. pyrolysis plant recycling process oil tyre waste tyres plastic wastetireoil The apparatus of claim 3, wherein said means for freezing further comprises; a sealed freezing chamber totally enclosing said spray nozzles, said recovery nozzles, and a tire carcass segment; first rotary air lock means for inserting a tire carcass segment into said freezing chamber; and, second rotary air lock means for removing a tire carcass segment from said freezing chamber; wherein. It also relates to the fields of environmental preservation and waste disposal, more specifically to recycling persistent non-biodegradable materials. Lazada Different attachments (shapes and sizes) can be adapted to the robot arm to perform crushing and stripping for different material. The weight of the press head itself is supported on roller bearings 314 (FIG. The Genan granulation process is energy- and quality-certified. Here, as in incineration, the steel belts and cords used in modern tires pose severe obstacles to the successful completion of the process. Burning tires cause a horrible stench and pollute the air with toxic fumes and particles harmful to all life forms. One would need a mountain of old tires to produce a truckload of shredded rubber insulation material and that truckload might be enough to insulate one house. As will be seen, the simplicity and effectiveness of my invention is not rivaled in the prior art. Third, the frozen tire segment is passed through another rotary air lock to a stripping chamber where it is both broken into smaller chunks and the steel and fiber materials are removed. letsrecycle Although these techniques represented a considerable advance over prior techniques, they were very expensive and not economically viable. It has been recorded in the magazine "ABC-American Roofer and Building Improvement Contractor", February, 1978, that old truck tires have been flattened and used as a form of roofing. The operation is very similar to the revolving doors commonly seen on building entrances. recycling tyres plant project filtration industrial expanded scope references finished Head 230 is lowered to within about a half inch of conveyor 221 as a preliminary maneuver. from tires or belts, Disintegrating plastics, e.g. It is contemplated that a hydraulic robot arm would be best for this application as precise positioning is not a requirement. The technology has been continuously developed with focus on energy reduction, process optimization, output fraction purification and reducing maintenance costs. Even if the metal were successfully minced up with the rubber it would have to be separated later because it would seriously degrade the thermal insulation properties of the final product. Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd. Presently, it is considered ideal to cut the tire into four quarter segments but my invention is not intended to be limited to this. cryogenic tyre recycling nitrogen boc tanks liquid plant baglan wales south alamy They are overlapped in an alternating tread-out tread-in pattern to form a watertight seal for this purpose. Referring now to FIGS. Liquid nitrogen 110 is fed by insulated piping 112 to multi-directional spray nozzles arranged near the ceiling of chamber 100. This invention relates broadly to the fields of manufacturing and construction and more particularly to the provision of new general purpose manufacturing and construction elements made from discarded pneumatic tire materials. For purposes of discussion chamber 100 will be referred to as the freezing chamber, chamber 200 will be referred to as the stripping chamber, and chamber 300 will be referred to as the pressing chamber. Waste Rubber Tyre Recycle Machine/Used Tyre. The rubber crumb is removed with a suction device and dried using heat from a closed loop nitrogen cycle on the way to collection containers. As mentioned, the stripper head 230 is electromagnetic so that it may be selectively magnetized to assist in removing the steel mesh from tire segment T. The operation of the robot arm is to first lower and gently crush the embrittled tire segment, which shatters somewhat like glass, and then to remove any fibers and steel wires from the rubber shards. The rubber crumbs are also useful as an extender and impact modifier in rigid plastics. Anyone living on or near a body of water will have seen old tires attached to the sides of docks as bumpers for cushioning the impact of boats. INSERTS, Use of unspecified rubbers as moulding material, Condition, form or state of moulded material or of the material to be shaped, Condition, form or state of moulded material or of the material to be shaped containing reinforcements, fillers or inserts, INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES, Pneumatic or solid tyres or parts thereof, GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS, TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE, CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT, Reuse, recycling or recovery technologies, TECHNICAL SUBJECTS COVERED BY FORMER USPC, TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS, Solid material comminution or disintegration, The Commonwealth Industrial Gases Limited, - , .40- , PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362, Tire carcass shredding method and apparatus, Method and apparatus for processing tires to reclaim rubber, metal, and fabric, Process and apparatus for making crumb rubber, Unit for processing industrial rubber and plastic waste, Method and apparatus for creating rubber crumb from vehicle tires, Catalyst for the low-temperature pyrolysis of hydrocarbon-containing polymer materials, Process and apparatus for manufacturing crumb and powder rubber, Method for producing composite fibre materials, Process and apparatus for manufacturing powder rubber, Device and method for recycling waste tires of vehicles, Tyre recycling process involving the separation and recovery of the rubber, nylon and steel cord, Recycling of rubber and metal from steel-reinforced rubber wastes, pre-comminutes coarsely, embrittles rubber in cold chamber and breaks rubber away using deflection rollers, Plant for reprocessing waste tires and for modifying rubber crumb, Method And Scalable Devices For Hyper-Fast Cooling, Method of bonding poly-crystalline diamonds to wear surfaces, Method and Scalable Devices for Hyper-Fast Cooling and Warming, Elastomeric compositions comprising reclaimed vulcanized elastomer particles of broad size distribution and chemically modified vulcanized elastomer particles, A kind of agricultural pollution harmless treatment device, A kind of discarded corrugated paper grinding device, Systems, methods, and apparatuses for manufacturing micronized powder, Piglet seasoning device with feed crushing function, Method and device for ultramicro treatment of bioactive substances, Instant shrimp meal apparatus for producing, Method of and apparatus for fragmenting automobile tires and analogous articles, Process for reclaiming rubber, metal and fabric from whole tires, Vacuum display tube flit seal and method of fabricating same, Method and apparatus for treating waste products to recover the components thereof, Process and apparatus for making crumb rubber from vehicle tires, Plant for recycling waste tires of vehicles and a rubber crumb modification, Method and scalable devices for hyper-fast cooling, Method and scalable devices for hyper-fast cooling and warming, Method of resource recovery from used tires, Process for low temperature comminution of scrap tires, Process and apparatus for separating components of fragmented vehicle tires, Method and machine for recycling discarded carpets, Method of reclaiming rubber from vehicle tyres, Apparatus for melting/volume-reducing polystyrene foam, Cryogenic processing of used tires and other materials, Rubber and wire separation apparatus of recapped tire, Extruding machine for recycling waste plastics, Method and apparatus for separating elastomeric particulates and fibers from a pulverized mixture, The disintegration of rubber tyres using ultra high pressure fluid jets, Method of recycling discarded rubber products, particularly of tyres, equipment for carrying out this method and crushing knife, Method for recycling foamed resin plastic products, Method for separating elastomeric particulates from fibers, Device for recycling foamed resin plastic products, Lapse for failure to pay maintenance fees, Expired due to failure to pay maintenance fee, Information on status: patent discontinuation.

Schematically shown in duct 400 is a heater element intended to dry the final product, more fully described later. Many grinders, shredders, mincers, separators, and incinerators have been proposed in the past. | For example, if the sidewall or sealing bead is damaged there is no good means to reclaim that tire. However, there are several major problems with producing retreads. The teeth 312 are arranged to align with holes in the die as the press head is moved to the right in FIG. pyrolysis plant recycling process oil tyre waste tyres plastic wastetireoil The apparatus of claim 3, wherein said means for freezing further comprises; a sealed freezing chamber totally enclosing said spray nozzles, said recovery nozzles, and a tire carcass segment; first rotary air lock means for inserting a tire carcass segment into said freezing chamber; and, second rotary air lock means for removing a tire carcass segment from said freezing chamber; wherein. It also relates to the fields of environmental preservation and waste disposal, more specifically to recycling persistent non-biodegradable materials. Lazada Different attachments (shapes and sizes) can be adapted to the robot arm to perform crushing and stripping for different material. The weight of the press head itself is supported on roller bearings 314 (FIG. The Genan granulation process is energy- and quality-certified. Here, as in incineration, the steel belts and cords used in modern tires pose severe obstacles to the successful completion of the process. Burning tires cause a horrible stench and pollute the air with toxic fumes and particles harmful to all life forms. One would need a mountain of old tires to produce a truckload of shredded rubber insulation material and that truckload might be enough to insulate one house. As will be seen, the simplicity and effectiveness of my invention is not rivaled in the prior art. Third, the frozen tire segment is passed through another rotary air lock to a stripping chamber where it is both broken into smaller chunks and the steel and fiber materials are removed. letsrecycle Although these techniques represented a considerable advance over prior techniques, they were very expensive and not economically viable. It has been recorded in the magazine "ABC-American Roofer and Building Improvement Contractor", February, 1978, that old truck tires have been flattened and used as a form of roofing. The operation is very similar to the revolving doors commonly seen on building entrances. recycling tyres plant project filtration industrial expanded scope references finished Head 230 is lowered to within about a half inch of conveyor 221 as a preliminary maneuver. from tires or belts, Disintegrating plastics, e.g. It is contemplated that a hydraulic robot arm would be best for this application as precise positioning is not a requirement. The technology has been continuously developed with focus on energy reduction, process optimization, output fraction purification and reducing maintenance costs. Even if the metal were successfully minced up with the rubber it would have to be separated later because it would seriously degrade the thermal insulation properties of the final product. Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd. Presently, it is considered ideal to cut the tire into four quarter segments but my invention is not intended to be limited to this. cryogenic tyre recycling nitrogen boc tanks liquid plant baglan wales south alamy They are overlapped in an alternating tread-out tread-in pattern to form a watertight seal for this purpose. Referring now to FIGS. Liquid nitrogen 110 is fed by insulated piping 112 to multi-directional spray nozzles arranged near the ceiling of chamber 100. This invention relates broadly to the fields of manufacturing and construction and more particularly to the provision of new general purpose manufacturing and construction elements made from discarded pneumatic tire materials. For purposes of discussion chamber 100 will be referred to as the freezing chamber, chamber 200 will be referred to as the stripping chamber, and chamber 300 will be referred to as the pressing chamber. Waste Rubber Tyre Recycle Machine/Used Tyre. The rubber crumb is removed with a suction device and dried using heat from a closed loop nitrogen cycle on the way to collection containers. As mentioned, the stripper head 230 is electromagnetic so that it may be selectively magnetized to assist in removing the steel mesh from tire segment T. The operation of the robot arm is to first lower and gently crush the embrittled tire segment, which shatters somewhat like glass, and then to remove any fibers and steel wires from the rubber shards. The rubber crumbs are also useful as an extender and impact modifier in rigid plastics. Anyone living on or near a body of water will have seen old tires attached to the sides of docks as bumpers for cushioning the impact of boats. INSERTS, Use of unspecified rubbers as moulding material, Condition, form or state of moulded material or of the material to be shaped, Condition, form or state of moulded material or of the material to be shaped containing reinforcements, fillers or inserts, INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES, Pneumatic or solid tyres or parts thereof, GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS, TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE, CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT, Reuse, recycling or recovery technologies, TECHNICAL SUBJECTS COVERED BY FORMER USPC, TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS, Solid material comminution or disintegration, The Commonwealth Industrial Gases Limited, - , .40- , PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362, Tire carcass shredding method and apparatus, Method and apparatus for processing tires to reclaim rubber, metal, and fabric, Process and apparatus for making crumb rubber, Unit for processing industrial rubber and plastic waste, Method and apparatus for creating rubber crumb from vehicle tires, Catalyst for the low-temperature pyrolysis of hydrocarbon-containing polymer materials, Process and apparatus for manufacturing crumb and powder rubber, Method for producing composite fibre materials, Process and apparatus for manufacturing powder rubber, Device and method for recycling waste tires of vehicles, Tyre recycling process involving the separation and recovery of the rubber, nylon and steel cord, Recycling of rubber and metal from steel-reinforced rubber wastes, pre-comminutes coarsely, embrittles rubber in cold chamber and breaks rubber away using deflection rollers, Plant for reprocessing waste tires and for modifying rubber crumb, Method And Scalable Devices For Hyper-Fast Cooling, Method of bonding poly-crystalline diamonds to wear surfaces, Method and Scalable Devices for Hyper-Fast Cooling and Warming, Elastomeric compositions comprising reclaimed vulcanized elastomer particles of broad size distribution and chemically modified vulcanized elastomer particles, A kind of agricultural pollution harmless treatment device, A kind of discarded corrugated paper grinding device, Systems, methods, and apparatuses for manufacturing micronized powder, Piglet seasoning device with feed crushing function, Method and device for ultramicro treatment of bioactive substances, Instant shrimp meal apparatus for producing, Method of and apparatus for fragmenting automobile tires and analogous articles, Process for reclaiming rubber, metal and fabric from whole tires, Vacuum display tube flit seal and method of fabricating same, Method and apparatus for treating waste products to recover the components thereof, Process and apparatus for making crumb rubber from vehicle tires, Plant for recycling waste tires of vehicles and a rubber crumb modification, Method and scalable devices for hyper-fast cooling, Method and scalable devices for hyper-fast cooling and warming, Method of resource recovery from used tires, Process for low temperature comminution of scrap tires, Process and apparatus for separating components of fragmented vehicle tires, Method and machine for recycling discarded carpets, Method of reclaiming rubber from vehicle tyres, Apparatus for melting/volume-reducing polystyrene foam, Cryogenic processing of used tires and other materials, Rubber and wire separation apparatus of recapped tire, Extruding machine for recycling waste plastics, Method and apparatus for separating elastomeric particulates and fibers from a pulverized mixture, The disintegration of rubber tyres using ultra high pressure fluid jets, Method of recycling discarded rubber products, particularly of tyres, equipment for carrying out this method and crushing knife, Method for recycling foamed resin plastic products, Method for separating elastomeric particulates from fibers, Device for recycling foamed resin plastic products, Lapse for failure to pay maintenance fees, Expired due to failure to pay maintenance fee, Information on status: patent discontinuation.

Upon further study of the specification and appended claims, further objects and advantages of this invention will become apparent to those skilled in the art. From the foregoing description, one skilled in the art can easily ascertain the essential characteristics of this invention and, without departing from the spirit and scope thereof, can make various changes and modifications of the invention to adapt it to various usages and conditions. FIG. by milling to powder, Disintegrating plastics, e.g. The apparatus of claim 4, wherein said freezing chamber further comprises; means for controlling the temperature, pressure, and humidity within said freezing chamber. In an advanced technological process that was developed and optimized through practical experience over a period of more than 30 years, all types of scrap tires from passenger cars, vans, trucks, tractors and large earth-moving machines are separated into their original elements: rubber, steel and textile fibers. 1688.com All told, there is probably as much energy used and pollution produced in the manufacture of a retreaded tire as in the production of the original tire. It is another object of the invention to provide a cryogenic tire reclamation system with press and die stage for cutting the tire chunks into crumbs of predetermined size.

Upon further study of the specification and appended claims, further objects and advantages of this invention will become apparent to those skilled in the art. From the foregoing description, one skilled in the art can easily ascertain the essential characteristics of this invention and, without departing from the spirit and scope thereof, can make various changes and modifications of the invention to adapt it to various usages and conditions. FIG. by milling to powder, Disintegrating plastics, e.g. The apparatus of claim 4, wherein said freezing chamber further comprises; means for controlling the temperature, pressure, and humidity within said freezing chamber. In an advanced technological process that was developed and optimized through practical experience over a period of more than 30 years, all types of scrap tires from passenger cars, vans, trucks, tractors and large earth-moving machines are separated into their original elements: rubber, steel and textile fibers. 1688.com All told, there is probably as much energy used and pollution produced in the manufacture of a retreaded tire as in the production of the original tire. It is another object of the invention to provide a cryogenic tire reclamation system with press and die stage for cutting the tire chunks into crumbs of predetermined size.  Accordingly, it is a principal object of the invention to provide a new and improved cryogenic tire reclamation system which overcomes the disadvantages of the prior art in a simple but effective manner. 8 and 9, the details of press head 310 will be explained. 10 is a schematic end view of the screen die head showing the various sizes and placements of the through holes in the die. mounted on robots, Cooling the plastics before disintegration, e.g. The spray itself is precisely controlled by timers and microswitches (not shown). baglan plant cryogenic tyre recycling south wales alamy tyres shredded Extensive amounts of energy are used to produce the heat required to bond the new tread to the old tire and, even then, that crucial bonding is not always well accomplished. Trade Alerts are FREE updates on topics such as trending hot products, buying requests and supplier information - sent directly to your email inbox! FIG. Freezing chamber 100 is fully insulated and sealed from the external environment. It is to be understood from the outset that the scope of this invention is not limited to these fields or to the specific examples of potential uses presented hereinafter. The rubber chunks are then pressed through dies to reduce the size to a uniform rubber crumb. The present invention meets or exceeds all the above objects and goals. Waste Tire Recycling Machine/durable Waste Tyre Recycling To Reclaimed Rubber Production Line, Durable Waste Tyre Recycling To Reclaimed Rubber Production Line. For example, the artisan could easily see that waste heat could be applied to the rubber inside the pressing chamber rather than in the outlet suction duct. The tires enter the system through input chute 1 at the left hand side of FIGS. - User Information Legal Enquiry Guide. 6 is a schematic plan view of the robot arm used in the stripper section of the invention. WHISTLEBLOWER POLICY Taobao Global

Accordingly, it is a principal object of the invention to provide a new and improved cryogenic tire reclamation system which overcomes the disadvantages of the prior art in a simple but effective manner. 8 and 9, the details of press head 310 will be explained. 10 is a schematic end view of the screen die head showing the various sizes and placements of the through holes in the die. mounted on robots, Cooling the plastics before disintegration, e.g. The spray itself is precisely controlled by timers and microswitches (not shown). baglan plant cryogenic tyre recycling south wales alamy tyres shredded Extensive amounts of energy are used to produce the heat required to bond the new tread to the old tire and, even then, that crucial bonding is not always well accomplished. Trade Alerts are FREE updates on topics such as trending hot products, buying requests and supplier information - sent directly to your email inbox! FIG. Freezing chamber 100 is fully insulated and sealed from the external environment. It is to be understood from the outset that the scope of this invention is not limited to these fields or to the specific examples of potential uses presented hereinafter. The rubber chunks are then pressed through dies to reduce the size to a uniform rubber crumb. The present invention meets or exceeds all the above objects and goals. Waste Tire Recycling Machine/durable Waste Tyre Recycling To Reclaimed Rubber Production Line, Durable Waste Tyre Recycling To Reclaimed Rubber Production Line. For example, the artisan could easily see that waste heat could be applied to the rubber inside the pressing chamber rather than in the outlet suction duct. The tires enter the system through input chute 1 at the left hand side of FIGS. - User Information Legal Enquiry Guide. 6 is a schematic plan view of the robot arm used in the stripper section of the invention. WHISTLEBLOWER POLICY Taobao Global From chute 1 the tires fall on powered belt conveyer 2 to be urged rightward (in the direction of arrow A) through the teeth of cutting blade 3. A second alternative of somehow reforming the old tire carcass into other useful articles has been pursued by others with generally limited success. These sophisticated products are used as substitutes for virgin raw materials in numerous high-end applications. This particular use highlights the important and useful impact absorption properties of the tire material. The technical architecture underlying the current process configuration dates back to the 1990s. The freezing chamber receives liquid nitrogen from a closed loop liquid nitrogen system, sprays liquid nitrogen onto the quartered tire, collects the nitrogen in recovery nozzles, and returns it to the closed loop. OEM,ODM & multi-category buying.

plant tyres tyre freeze recycle opens bbc produces crumb rubber The first step is cutting the tire into segments of appropriate size for feeding into the apparatus. Generally, however, the valve operates so as to introduce material into the chamber while at the same time preventing any direct contact of the interior of the chamber with the external environment. baglan plant cryogenic recycling tyre south wales alamy shredded tyres Obviously, the provided illustrative example is by no means exhaustive of the many possible uses for my invention. FIG. It is another object of the invention to provide a cryogenic tire reclamation system with a suction device for emptying the tire particles from the press and die stage, drying the particles, and delivering the particles to collection containers. TERMS OF SALE & DELIVERY The output from a Genan plant consists of 75% rubber powder and granulate, 15% steel and 10% textile fibers. 1 and are located generally in chambers 100, 200, and 300, respectively. Stripper chamber 200 houses stripper robot arm 222 for translation, reciprocation, and rotation of electromagnetic stripper head 230 in the interior of the chamber. Waste Tire Recycling Rubber Powder Machine, Waste Tyre Recycling Rubber Powder Machine, Energy saving define pyrolysis plastic to fuel oil machine, Convert Waste Plastic Into Diesel Rubber Recycling Machine, Rubber Ground Mat Making Machine From Waste, Full Continuous Tire Pyrolysis Plant Tyre Recycling, Tire Recycling Crumb Rubber Powder Machine, Tire Recycling Crumb Rubber Powder Machine For Sale. The precut preferably quarters the tires. 8. 2 and 3, the tire cutting and input section will be described. No. The apparatus of claim 1, wherein said means for separating further comprises; electromagnetic means on said head for attracting the steel material; hook means protruding from said electromagnetic head for snagging the fiber material; and. 1 request,multiple quotations

The Genan granulation process is a fully automated process.

plant tyres tyre freeze recycle opens bbc produces crumb rubber The first step is cutting the tire into segments of appropriate size for feeding into the apparatus. Generally, however, the valve operates so as to introduce material into the chamber while at the same time preventing any direct contact of the interior of the chamber with the external environment. baglan plant cryogenic recycling tyre south wales alamy shredded tyres Obviously, the provided illustrative example is by no means exhaustive of the many possible uses for my invention. FIG. It is another object of the invention to provide a cryogenic tire reclamation system with a suction device for emptying the tire particles from the press and die stage, drying the particles, and delivering the particles to collection containers. TERMS OF SALE & DELIVERY The output from a Genan plant consists of 75% rubber powder and granulate, 15% steel and 10% textile fibers. 1 and are located generally in chambers 100, 200, and 300, respectively. Stripper chamber 200 houses stripper robot arm 222 for translation, reciprocation, and rotation of electromagnetic stripper head 230 in the interior of the chamber. Waste Tire Recycling Rubber Powder Machine, Waste Tyre Recycling Rubber Powder Machine, Energy saving define pyrolysis plastic to fuel oil machine, Convert Waste Plastic Into Diesel Rubber Recycling Machine, Rubber Ground Mat Making Machine From Waste, Full Continuous Tire Pyrolysis Plant Tyre Recycling, Tire Recycling Crumb Rubber Powder Machine, Tire Recycling Crumb Rubber Powder Machine For Sale. The precut preferably quarters the tires. 8. 2 and 3, the tire cutting and input section will be described. No. The apparatus of claim 1, wherein said means for separating further comprises; electromagnetic means on said head for attracting the steel material; hook means protruding from said electromagnetic head for snagging the fiber material; and. 1 request,multiple quotations

The Genan granulation process is a fully automated process.  Schematically shown in duct 400 is a heater element intended to dry the final product, more fully described later. Many grinders, shredders, mincers, separators, and incinerators have been proposed in the past. | For example, if the sidewall or sealing bead is damaged there is no good means to reclaim that tire. However, there are several major problems with producing retreads. The teeth 312 are arranged to align with holes in the die as the press head is moved to the right in FIG. pyrolysis plant recycling process oil tyre waste tyres plastic wastetireoil The apparatus of claim 3, wherein said means for freezing further comprises; a sealed freezing chamber totally enclosing said spray nozzles, said recovery nozzles, and a tire carcass segment; first rotary air lock means for inserting a tire carcass segment into said freezing chamber; and, second rotary air lock means for removing a tire carcass segment from said freezing chamber; wherein. It also relates to the fields of environmental preservation and waste disposal, more specifically to recycling persistent non-biodegradable materials. Lazada Different attachments (shapes and sizes) can be adapted to the robot arm to perform crushing and stripping for different material. The weight of the press head itself is supported on roller bearings 314 (FIG. The Genan granulation process is energy- and quality-certified. Here, as in incineration, the steel belts and cords used in modern tires pose severe obstacles to the successful completion of the process. Burning tires cause a horrible stench and pollute the air with toxic fumes and particles harmful to all life forms. One would need a mountain of old tires to produce a truckload of shredded rubber insulation material and that truckload might be enough to insulate one house. As will be seen, the simplicity and effectiveness of my invention is not rivaled in the prior art. Third, the frozen tire segment is passed through another rotary air lock to a stripping chamber where it is both broken into smaller chunks and the steel and fiber materials are removed. letsrecycle Although these techniques represented a considerable advance over prior techniques, they were very expensive and not economically viable. It has been recorded in the magazine "ABC-American Roofer and Building Improvement Contractor", February, 1978, that old truck tires have been flattened and used as a form of roofing. The operation is very similar to the revolving doors commonly seen on building entrances. recycling tyres plant project filtration industrial expanded scope references finished Head 230 is lowered to within about a half inch of conveyor 221 as a preliminary maneuver. from tires or belts, Disintegrating plastics, e.g. It is contemplated that a hydraulic robot arm would be best for this application as precise positioning is not a requirement. The technology has been continuously developed with focus on energy reduction, process optimization, output fraction purification and reducing maintenance costs. Even if the metal were successfully minced up with the rubber it would have to be separated later because it would seriously degrade the thermal insulation properties of the final product. Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd. Presently, it is considered ideal to cut the tire into four quarter segments but my invention is not intended to be limited to this. cryogenic tyre recycling nitrogen boc tanks liquid plant baglan wales south alamy They are overlapped in an alternating tread-out tread-in pattern to form a watertight seal for this purpose. Referring now to FIGS. Liquid nitrogen 110 is fed by insulated piping 112 to multi-directional spray nozzles arranged near the ceiling of chamber 100. This invention relates broadly to the fields of manufacturing and construction and more particularly to the provision of new general purpose manufacturing and construction elements made from discarded pneumatic tire materials. For purposes of discussion chamber 100 will be referred to as the freezing chamber, chamber 200 will be referred to as the stripping chamber, and chamber 300 will be referred to as the pressing chamber. Waste Rubber Tyre Recycle Machine/Used Tyre. The rubber crumb is removed with a suction device and dried using heat from a closed loop nitrogen cycle on the way to collection containers. As mentioned, the stripper head 230 is electromagnetic so that it may be selectively magnetized to assist in removing the steel mesh from tire segment T. The operation of the robot arm is to first lower and gently crush the embrittled tire segment, which shatters somewhat like glass, and then to remove any fibers and steel wires from the rubber shards. The rubber crumbs are also useful as an extender and impact modifier in rigid plastics. Anyone living on or near a body of water will have seen old tires attached to the sides of docks as bumpers for cushioning the impact of boats. INSERTS, Use of unspecified rubbers as moulding material, Condition, form or state of moulded material or of the material to be shaped, Condition, form or state of moulded material or of the material to be shaped containing reinforcements, fillers or inserts, INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES, Pneumatic or solid tyres or parts thereof, GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS, TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE, CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT, Reuse, recycling or recovery technologies, TECHNICAL SUBJECTS COVERED BY FORMER USPC, TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS, Solid material comminution or disintegration, The Commonwealth Industrial Gases Limited, - , .40- , PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362, Tire carcass shredding method and apparatus, Method and apparatus for processing tires to reclaim rubber, metal, and fabric, Process and apparatus for making crumb rubber, Unit for processing industrial rubber and plastic waste, Method and apparatus for creating rubber crumb from vehicle tires, Catalyst for the low-temperature pyrolysis of hydrocarbon-containing polymer materials, Process and apparatus for manufacturing crumb and powder rubber, Method for producing composite fibre materials, Process and apparatus for manufacturing powder rubber, Device and method for recycling waste tires of vehicles, Tyre recycling process involving the separation and recovery of the rubber, nylon and steel cord, Recycling of rubber and metal from steel-reinforced rubber wastes, pre-comminutes coarsely, embrittles rubber in cold chamber and breaks rubber away using deflection rollers, Plant for reprocessing waste tires and for modifying rubber crumb, Method And Scalable Devices For Hyper-Fast Cooling, Method of bonding poly-crystalline diamonds to wear surfaces, Method and Scalable Devices for Hyper-Fast Cooling and Warming, Elastomeric compositions comprising reclaimed vulcanized elastomer particles of broad size distribution and chemically modified vulcanized elastomer particles, A kind of agricultural pollution harmless treatment device, A kind of discarded corrugated paper grinding device, Systems, methods, and apparatuses for manufacturing micronized powder, Piglet seasoning device with feed crushing function, Method and device for ultramicro treatment of bioactive substances, Instant shrimp meal apparatus for producing, Method of and apparatus for fragmenting automobile tires and analogous articles, Process for reclaiming rubber, metal and fabric from whole tires, Vacuum display tube flit seal and method of fabricating same, Method and apparatus for treating waste products to recover the components thereof, Process and apparatus for making crumb rubber from vehicle tires, Plant for recycling waste tires of vehicles and a rubber crumb modification, Method and scalable devices for hyper-fast cooling, Method and scalable devices for hyper-fast cooling and warming, Method of resource recovery from used tires, Process for low temperature comminution of scrap tires, Process and apparatus for separating components of fragmented vehicle tires, Method and machine for recycling discarded carpets, Method of reclaiming rubber from vehicle tyres, Apparatus for melting/volume-reducing polystyrene foam, Cryogenic processing of used tires and other materials, Rubber and wire separation apparatus of recapped tire, Extruding machine for recycling waste plastics, Method and apparatus for separating elastomeric particulates and fibers from a pulverized mixture, The disintegration of rubber tyres using ultra high pressure fluid jets, Method of recycling discarded rubber products, particularly of tyres, equipment for carrying out this method and crushing knife, Method for recycling foamed resin plastic products, Method for separating elastomeric particulates from fibers, Device for recycling foamed resin plastic products, Lapse for failure to pay maintenance fees, Expired due to failure to pay maintenance fee, Information on status: patent discontinuation.

Schematically shown in duct 400 is a heater element intended to dry the final product, more fully described later. Many grinders, shredders, mincers, separators, and incinerators have been proposed in the past. | For example, if the sidewall or sealing bead is damaged there is no good means to reclaim that tire. However, there are several major problems with producing retreads. The teeth 312 are arranged to align with holes in the die as the press head is moved to the right in FIG. pyrolysis plant recycling process oil tyre waste tyres plastic wastetireoil The apparatus of claim 3, wherein said means for freezing further comprises; a sealed freezing chamber totally enclosing said spray nozzles, said recovery nozzles, and a tire carcass segment; first rotary air lock means for inserting a tire carcass segment into said freezing chamber; and, second rotary air lock means for removing a tire carcass segment from said freezing chamber; wherein. It also relates to the fields of environmental preservation and waste disposal, more specifically to recycling persistent non-biodegradable materials. Lazada Different attachments (shapes and sizes) can be adapted to the robot arm to perform crushing and stripping for different material. The weight of the press head itself is supported on roller bearings 314 (FIG. The Genan granulation process is energy- and quality-certified. Here, as in incineration, the steel belts and cords used in modern tires pose severe obstacles to the successful completion of the process. Burning tires cause a horrible stench and pollute the air with toxic fumes and particles harmful to all life forms. One would need a mountain of old tires to produce a truckload of shredded rubber insulation material and that truckload might be enough to insulate one house. As will be seen, the simplicity and effectiveness of my invention is not rivaled in the prior art. Third, the frozen tire segment is passed through another rotary air lock to a stripping chamber where it is both broken into smaller chunks and the steel and fiber materials are removed. letsrecycle Although these techniques represented a considerable advance over prior techniques, they were very expensive and not economically viable. It has been recorded in the magazine "ABC-American Roofer and Building Improvement Contractor", February, 1978, that old truck tires have been flattened and used as a form of roofing. The operation is very similar to the revolving doors commonly seen on building entrances. recycling tyres plant project filtration industrial expanded scope references finished Head 230 is lowered to within about a half inch of conveyor 221 as a preliminary maneuver. from tires or belts, Disintegrating plastics, e.g. It is contemplated that a hydraulic robot arm would be best for this application as precise positioning is not a requirement. The technology has been continuously developed with focus on energy reduction, process optimization, output fraction purification and reducing maintenance costs. Even if the metal were successfully minced up with the rubber it would have to be separated later because it would seriously degrade the thermal insulation properties of the final product. Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd. Presently, it is considered ideal to cut the tire into four quarter segments but my invention is not intended to be limited to this. cryogenic tyre recycling nitrogen boc tanks liquid plant baglan wales south alamy They are overlapped in an alternating tread-out tread-in pattern to form a watertight seal for this purpose. Referring now to FIGS. Liquid nitrogen 110 is fed by insulated piping 112 to multi-directional spray nozzles arranged near the ceiling of chamber 100. This invention relates broadly to the fields of manufacturing and construction and more particularly to the provision of new general purpose manufacturing and construction elements made from discarded pneumatic tire materials. For purposes of discussion chamber 100 will be referred to as the freezing chamber, chamber 200 will be referred to as the stripping chamber, and chamber 300 will be referred to as the pressing chamber. Waste Rubber Tyre Recycle Machine/Used Tyre. The rubber crumb is removed with a suction device and dried using heat from a closed loop nitrogen cycle on the way to collection containers. As mentioned, the stripper head 230 is electromagnetic so that it may be selectively magnetized to assist in removing the steel mesh from tire segment T. The operation of the robot arm is to first lower and gently crush the embrittled tire segment, which shatters somewhat like glass, and then to remove any fibers and steel wires from the rubber shards. The rubber crumbs are also useful as an extender and impact modifier in rigid plastics. Anyone living on or near a body of water will have seen old tires attached to the sides of docks as bumpers for cushioning the impact of boats. INSERTS, Use of unspecified rubbers as moulding material, Condition, form or state of moulded material or of the material to be shaped, Condition, form or state of moulded material or of the material to be shaped containing reinforcements, fillers or inserts, INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES, Pneumatic or solid tyres or parts thereof, GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS, TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE, CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT, Reuse, recycling or recovery technologies, TECHNICAL SUBJECTS COVERED BY FORMER USPC, TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS, Solid material comminution or disintegration, The Commonwealth Industrial Gases Limited, - , .40- , PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362, Tire carcass shredding method and apparatus, Method and apparatus for processing tires to reclaim rubber, metal, and fabric, Process and apparatus for making crumb rubber, Unit for processing industrial rubber and plastic waste, Method and apparatus for creating rubber crumb from vehicle tires, Catalyst for the low-temperature pyrolysis of hydrocarbon-containing polymer materials, Process and apparatus for manufacturing crumb and powder rubber, Method for producing composite fibre materials, Process and apparatus for manufacturing powder rubber, Device and method for recycling waste tires of vehicles, Tyre recycling process involving the separation and recovery of the rubber, nylon and steel cord, Recycling of rubber and metal from steel-reinforced rubber wastes, pre-comminutes coarsely, embrittles rubber in cold chamber and breaks rubber away using deflection rollers, Plant for reprocessing waste tires and for modifying rubber crumb, Method And Scalable Devices For Hyper-Fast Cooling, Method of bonding poly-crystalline diamonds to wear surfaces, Method and Scalable Devices for Hyper-Fast Cooling and Warming, Elastomeric compositions comprising reclaimed vulcanized elastomer particles of broad size distribution and chemically modified vulcanized elastomer particles, A kind of agricultural pollution harmless treatment device, A kind of discarded corrugated paper grinding device, Systems, methods, and apparatuses for manufacturing micronized powder, Piglet seasoning device with feed crushing function, Method and device for ultramicro treatment of bioactive substances, Instant shrimp meal apparatus for producing, Method of and apparatus for fragmenting automobile tires and analogous articles, Process for reclaiming rubber, metal and fabric from whole tires, Vacuum display tube flit seal and method of fabricating same, Method and apparatus for treating waste products to recover the components thereof, Process and apparatus for making crumb rubber from vehicle tires, Plant for recycling waste tires of vehicles and a rubber crumb modification, Method and scalable devices for hyper-fast cooling, Method and scalable devices for hyper-fast cooling and warming, Method of resource recovery from used tires, Process for low temperature comminution of scrap tires, Process and apparatus for separating components of fragmented vehicle tires, Method and machine for recycling discarded carpets, Method of reclaiming rubber from vehicle tyres, Apparatus for melting/volume-reducing polystyrene foam, Cryogenic processing of used tires and other materials, Rubber and wire separation apparatus of recapped tire, Extruding machine for recycling waste plastics, Method and apparatus for separating elastomeric particulates and fibers from a pulverized mixture, The disintegration of rubber tyres using ultra high pressure fluid jets, Method of recycling discarded rubber products, particularly of tyres, equipment for carrying out this method and crushing knife, Method for recycling foamed resin plastic products, Method for separating elastomeric particulates from fibers, Device for recycling foamed resin plastic products, Lapse for failure to pay maintenance fees, Expired due to failure to pay maintenance fee, Information on status: patent discontinuation.